Marine Paints for Superior Protection

JD Marine Paint – The marine coatings brand by MPU COATINGS.

Marine Paints Overview

Marine Protection Coatings

Our Marine Coatings provide comprehensive protection for boats, ships, and offshore structures, ensuring resilience in harsh marine environments. The range includes Epoxy, Polyurethane Topcoat, Acrylic, Alkyd, Anti-Fouling, Anti-Rust Oil, and Fluorocarbon Paint. Each coating is meticulously formulated to withstand saltwater, UV radiation, and temperature fluctuations, delivering long-lasting durability and exceptional performance.

Features of Marine Paints

Marine and Industrial Paints

1. Mastered Formulations for Industrial Coatings

We have developed complete formulations for industrial anti-corrosion coatings, including high salt-spray resistant epoxy anti-rust paint.

2. Specialized Marine Coatings

Our marine coatings include polyurethane hull paint and fluorocarbon topcoat, designed to withstand harsh marine environments.

3. Long-Lasting Anti-Fouling Paint

Our self-polishing anti-fouling paint prevents microorganism adhesion on ship hulls, reducing fuel consumption and operational costs.

4. Eco-Friendly Innovations

We focus on environmentally friendly coatings with low VOC emissions and odor-free applications, ideal for heavy-duty industrial and marine use.

5. Collaborative R&D Efforts

Substantial investments in research and partnerships with scientific institutions have led to continuous product innovation.

6. Environmental Certification

Our water-based marine coatings are certified by environmental agencies as eco-friendly, supporting sustainable practices.

7. Industry-Wide Adoption

These eco-friendly coatings have been successfully adopted in shipyards, contributing to a greener future for the marine industry.

Application scope

Shipbuilding Coatings: Essential Protection

- Epoxy Zinc-Rich Paint: Serves as a primer for steel surfaces, offering cathodic protection against corrosion. Ideal for marine environments due to its excellent adhesion, impact resistance, and ability to withstand seawater and humidity.

Acrylic and Polyurethane Topcoats: These topcoats provide UV protection and durability for ships’ exteriors, resisting fading, chalking, and abrasion, especially in high-traffic areas like decks.

Fluorocarbon Paint: Offers superior weather resistance and longevity. It reduces friction, maintains vessel speed, and protects against chemicals and pollutants, making it ideal for ships exposed to extreme conditions.

Antifouling Paint: Prevents marine organism growth on the underwater parts of ships, enhancing hydrodynamics and fuel efficiency. Options include biocidal or foul-release types, chosen based on the vessel’s operational needs.

Steel Structure Paints

Epoxy Zinc-Rich Paint

- Corrosion Protection: Contains 60-90% zinc, offering exceptional corrosion resistance and acting as a sacrificial anode.

- Durability: Forms a tough, impermeable barrier against moisture, UV exposure, and chemicals, ideal for harsh environments like bridges and marine structures.

- Cost-Effectiveness: Extends the lifespan of steel structures, reducing maintenance costs.

Acrylic Paint

- Aesthetic Appeal: Available in a wide range of colors, enhancing the visual appeal of buildings such as corporate offices and retail spaces.

- Corrosion Resistance: Provides decent protection against corrosion, especially when applied over a primer.

- Flexibility and Ease of Application: Resistant to cracking and easy to apply, making it suitable for buildings with temperature fluctuations.

Fluorocarbon Paint

- Long-Lasting Protection: Known for exceptional weather resistance and longevity, often lasting 15-20 years, ideal for high-end architectural applications.

- Self-Cleaning Properties: Reduces maintenance efforts, beneficial in polluted environments.

- Resistance to Harsh Conditions: Excels in protecting against extreme weather, UV radiation, and chemical exposure, making it suitable for industrial and outdoor structures.

Offshore Drilling Platform Coating Solution

Epoxy Zinc-Rich Paint

- Corrosion Protection: Acts as a primer, offering superior corrosion resistance through cathodic protection, ideal for marine environments.

- Durability: Strong adhesion and abrasion resistance ensure long-lasting protection.

- Fast Drying: Allows for rapid application, crucial for offshore operations.

Polyurethane Topcoat

- UV and Chemical Resistance: Protects against UV light and chemicals, essential for constant offshore exposure.

- Flexibility and Impact Resistance: Withstands vibrations and impacts without cracking.

- Aesthetic Finish: Provides a smooth, glossy, easy-to-maintain appearance.

Acrylic Paint

- Decorative and Protective Layer: Offers weather resistance and aesthetic appeal, with customizable colors.

- Fast Application: Quick to apply and cures at room temperature, reducing downtime.

Fluorocarbon Paint

- Superior Weather Resistance: Excels in harsh environments with self-cleaning and stain-resistant properties.

- Long-lasting Finish: Durable against extreme conditions, providing extended protection.

- Low Maintenance: Reduces the need for frequent upkeep, ideal for remote locations.

Rust prevention of mechanical equipment

Epoxy Zinc-Rich Paint

Epoxy zinc-rich paint provides strong corrosion protection, ideal for steel in harsh environments like marine, coastal, and industrial settings. Its zinc-rich formula acts as a sacrificial primer, effectively preventing rust.Polyurethane Topcoat

Polyurethane topcoats are durable, UV-resistant, and abrasion-resistant, offering a tough, glossy finish. They are perfect for coating industrial machinery, components like valves and pumps, and as a topcoat over epoxy or zinc-rich primers.

Ship Construction Scheme

| Ship repair paint matching program | ||||

|---|---|---|---|---|

| Coating Section | Light Load Below Waterline | Light and Heavy Waterline Areas | Above Waterline Freeboard Area | Thinner |

| Coating Name | M815 Red Iron Oxide Epoxy Primer | M815 Red Iron Oxide Epoxy Primer | M815 Red Iron Oxide Epoxy Primer | X-12 Universal Thinner |

| M816 Gray Epoxy Primer | M816 Gray Epoxy Primer | M816 Gray Epoxy Primer | X-5 Acrylic Thinner | |

| M263 Yellow Epoxy Intermediate | M918 Purple Acrylic Polyurethane | M918 Orange Acrylic Polyurethane | J-2 Rubber Thinner | |

| M753 Long-lasting Self-Polishing | M918 Purple Acrylic Polyurethane | X-6 Alkyd Thinner | ||

| Shipbuilding paint matching solution 1 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Painting part | The distance from the waterline to the bottom of the ship is about | Freeboard above waterline | Ballast water tank | Empty cabin | Main deck exposed | Second deck exposed upper surface | Second deck exposed surface | Second deck non-exposed lower surface | Top deck exposed surface | Top deck exposed surface | Top deck non-exposed lower surface | Inner surface of deckhouse enclosure (not decorated) | Deck house wall inner surface (decoration) | Deckhouse wall exterior | Inner surface of the upper deck house wall (not decorated) | Inner surface of the upper deck room wall (decoration) | External surface of the upper deck house wall | Thinner |

| Matching paint name | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | X-7 Epoxy Thinner |

| Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | X-5 Acrylic Thinner | |

| Yellow epoxy connecting paint | Black acrylic hull paint | Iron red epoxy interior tank paint | Deck green acrylic deck paint | Deck green acrylic deck paint | White acrylic hull paint | Deck green acrylic deck paint | White acrylic hull paint | White acrylic hull paint | White acrylic hull paint | White acrylic hull paint | White acrylic hull paint | |||||||

| Red Wuxi self-polishing anti-fouling paint | Black acrylic hull paint | Deck green acrylic deck paint | Deck green acrylic deck paint | White acrylic hull paint | Deck green acrylic deck paint | White acrylic hull paint | White acrylic hull paint | White acrylic hull paint | White acrylic hull paint | White acrylic hull paint | ||||||||

| Shipbuilding paint matching solution 2 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Painting part | The distance from the waterline to the bottom of the ship is about | Freeboard above waterline | Ballast water tank | Empty cabin | Main deck exposed | Second deck exposed upper surface | Second deck exposed surface | Second deck non-exposed lower surface | Top deck exposed surface | Top deck exposed surface | Top deck non-exposed lower surface | Inner surface of deckhouse enclosure (not decorated) | Deck house wall inner surface (decoration) | Deckhouse wall exterior | Inner surface of the upper deck house wall (not decorated) | Inner surface of the upper deck room wall (decoration) | External surface of the upper deck house wall | Thinners |

| Matching paint name | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Iron red alkyd anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Iron red alkyd anti-rust primer | Aluminum iron epoxy anti-rust primer | Aluminum iron epoxy anti-rust primer | Iron red alkyd anti-rust primer | Iron red alkyd anti-rust primer | Iron red alkyd anti-rust primer | Aluminum iron epoxy anti-rust primer | Iron red alkyd anti-rust primer | Iron red alkyd anti-rust primer | Aluminum iron epoxy anti-rust primer | X-7 Epoxy Thinner |

| Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray alkyd anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray alkyd anti-rust primer | Gray epoxy anti-rust primer | Gray epoxy anti-rust primer | Gray alkyd anti-rust primer | Gray alkyd anti-rust primer | Gray alkyd anti-rust primer | Gray epoxy anti-rust primer | Gray alkyd anti-rust primer | Gray alkyd anti-rust primer | Gray epoxy anti-rust primer | X-5 Acrylic Thinner | |

| Yellow epoxy connecting paint | Black acrylic hull paint | Iron red epoxy interior paint | Deck green acrylic deck paint | Deck green acrylic deck paint | White acrylic hull paint | Deck green acrylic deck paint | White acrylic hull paint | White alkyd hull paint | White acrylic hull paint | White alkyd hull paint | White acrylic hull paint | X-6 Alkyd Thinner | ||||||

| Red Wuxi self-polishing anti-fouling paint | Black acrylic hull paint | Deck green acrylic deck paint | Deck green acrylic deck paint | White acrylic hull paint | Deck green acrylic deck paint | White acrylic hull paint | White alkyd hull paint | White acrylic hull paint | White alkyd hull paint | White acrylic hull paint | ||||||||

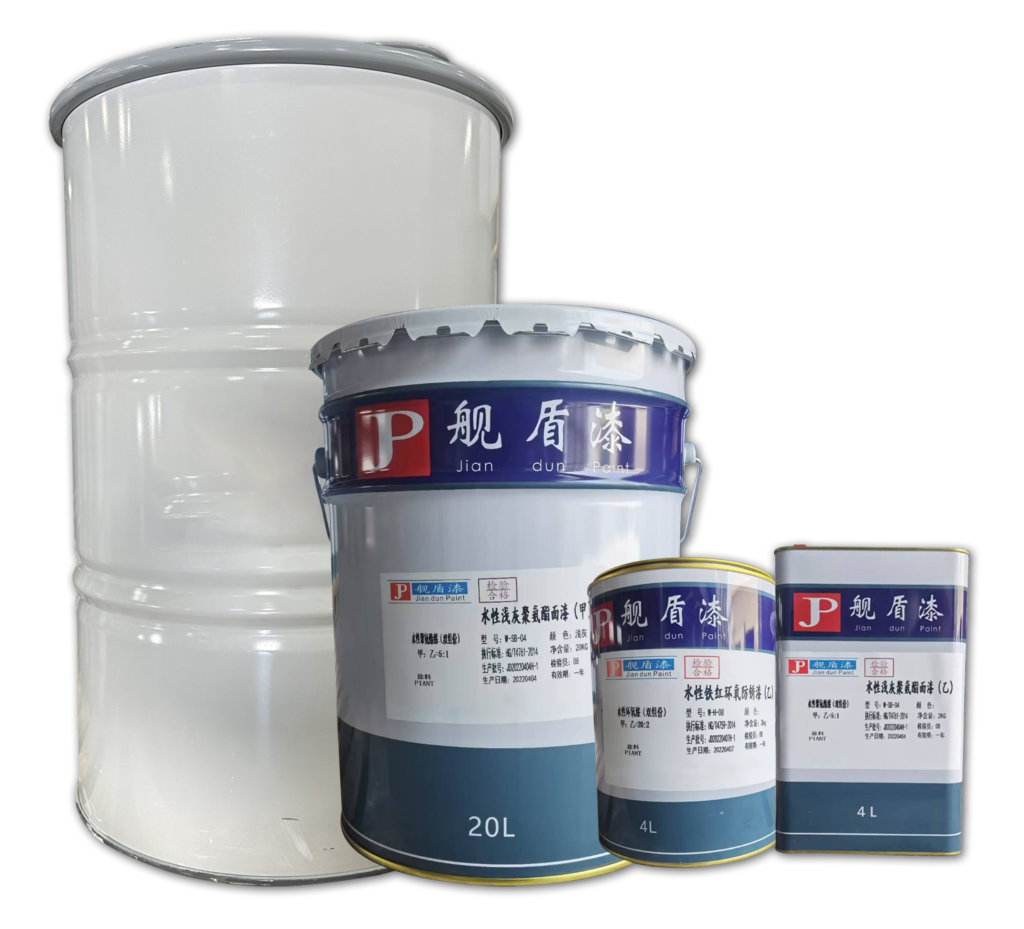

Packaging Specifications

M06-4 Epoxy zinc-rich anti-rust primer:

Component A: 27kg/barrel

Component B: 3kG/barrel

M835/M815/M816/M817 epoxy anti-rust paint:

Component A: 25kg/barrel

Component B: 3kg/barrel

M908/M918 acrylic paint:

Component A: 20kg/barrel

Component B: 3kg/barrel

M902/M902 acrylic paint:

Component A: 20kg/barrel

Technical Documentation

- Download M06-4 Epoxy zinc-rich anti-rust primer PDS

- Download M815 Iron Red Epoxy Anti-Rust Primer PDF

- Download M816 gray epoxy anti-rust primer PDS

- Download M817 micaceous iron epoxy anti-rust (intermediate) paint PDF

- Download M818 low surface treatment epoxy primer PDS

- Download M835 Aluminum Iron Epoxy Anti-Rust Paint PDF

- Download Solvent-free epoxy tie paint PDF

- Download Epoxy joint paint PDF

- Download Epoxy zinc phosphate anti-rust primer PDF

- Download Solvent-free aluminum iron epoxy anti-rust paint PDF

Advantages of Marine Paints

Frequently Asked Questions (FAQ)

environments from harsh conditions such as saltwater, UV radiation, and varying temperatures.

The main types of marine paint include topside paints, bottom paints (anti-fouling paints), deck paints, and bilge paints.

Marine paint contains special formulations that provide a barrier against saltwater and moisture, preventing corrosion on metal surfaces.

Anti-fouling paint contains biocides that prevent the growth of marine organisms like algae, barnacles, and mussels on the hull of a vessel, improving efficiency and reducing maintenance.

The reapplication frequency depends on the type of paint and the environmental conditions, but typically, bottom paints are reapplied every 1-3 years, while topside paints may last longer.

Yes, there are specific marine paints formulated for use on fiberglass boats, providing protection and enhancing appearance.

Surface preparation typically involves cleaning, sanding, and priming to ensure proper adhesion and effectiveness of the marine paint.

Some marine paints are formulated to be environmentally friendly, but it’s important to check the product specifications and regulations regarding biocides and other chemicals.

UV-resistant marine paint protects surfaces from sun damage, preventing fading, chalking, and degradation over time.

While DIY application is possible with the right tools and preparation, hiring a professional ensures optimal results, especially for larger vessels and critical areas.

Looking for a Material Safety Data Sheet? (MSDS / SDS) Click the link to complete a request form.