Running Track

Si-PU Sports Cotings:A range of indoor and outdoor flooring options to suit any sporting or ftness space

Your trusted supplier of Si-PU Running Track coatings

MPU is dedicated to developing and producing high-quality, environmentally-friendly materials for sports courts, tracks, and flooring. Our Si-PU products have undergone rigorous testing, including 3000 hours of aging tests, 100 cycles of -30°C to +50°C temperature fluctuations, and 168 hours in 60°C water, resulting in a weight loss rate of ≤0.8%. Our coatings do not bleed or seep oil and have passed mold tests, proving they do not mildew, rot, or emit odors.

Designed for OEM/ODM, our custom coatings can be tailored to your specific brand, color, packaging, and application needs. Trust our chemical expertise to deliver solutions that exceed expectations. Contact MPU COATINGS now to elevate your sports projects.

Si-PU Running Track System

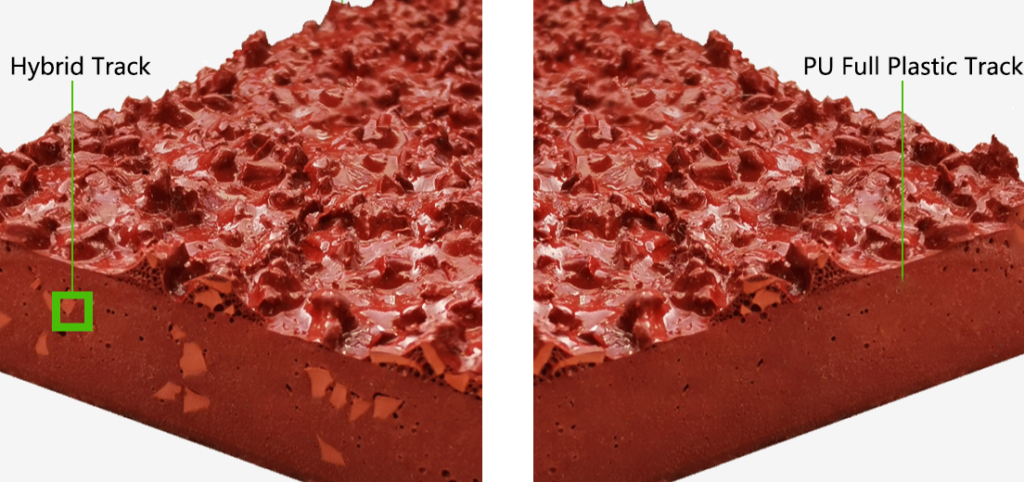

PU Full Plastic Track & Hybrid Track

Si-PU elastic layer is a high-performance sports track material known for its excellent cushioning, strong adhesion, and self-leveling properties. It is easy to install, has outstanding anti-aging capabilities, and maintains chemical stability post-installation, making it an ideal choice for durable and reliable sports tracks.

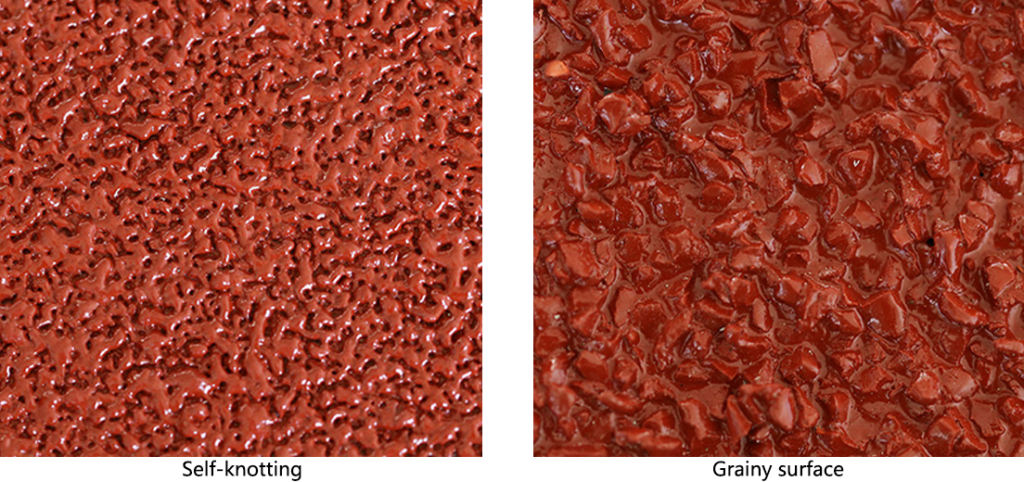

Self-knottng & Grainy surface

◆ Sprayed Granular Surface Layer

After the strengthening layer has cured at room temperature, a mixture of high-purity polyurethane compounds and small-grain, high-polymer content elastic particles is blended in a specific ratio and evenly stirred. This mixture is then applied using professional high-pressure equipment, forming a 2-3mm thick granular surface layer.

◆ Self-texturing Surface Layer

After the strengthening layer has cured at room temperature, specialized viscous polyurethane material is applied using professional high-pressure equipment, forming a 2-3mm thick surface layer with distinct concave-convex textures.

| Full Plastic VS Hybrid Track | ||

|---|---|---|

| Characteristic | Full Plastic Track | Hybrid Track |

| Wear Resistance | High | Medium |

| Elasticity | Excellent | Good |

| Lifespan | Over 8 years | 5-8 years |

| Cost | High | Medium |

| Maintenance Requirement | LOW | Medium |

PU Full Plastic Track

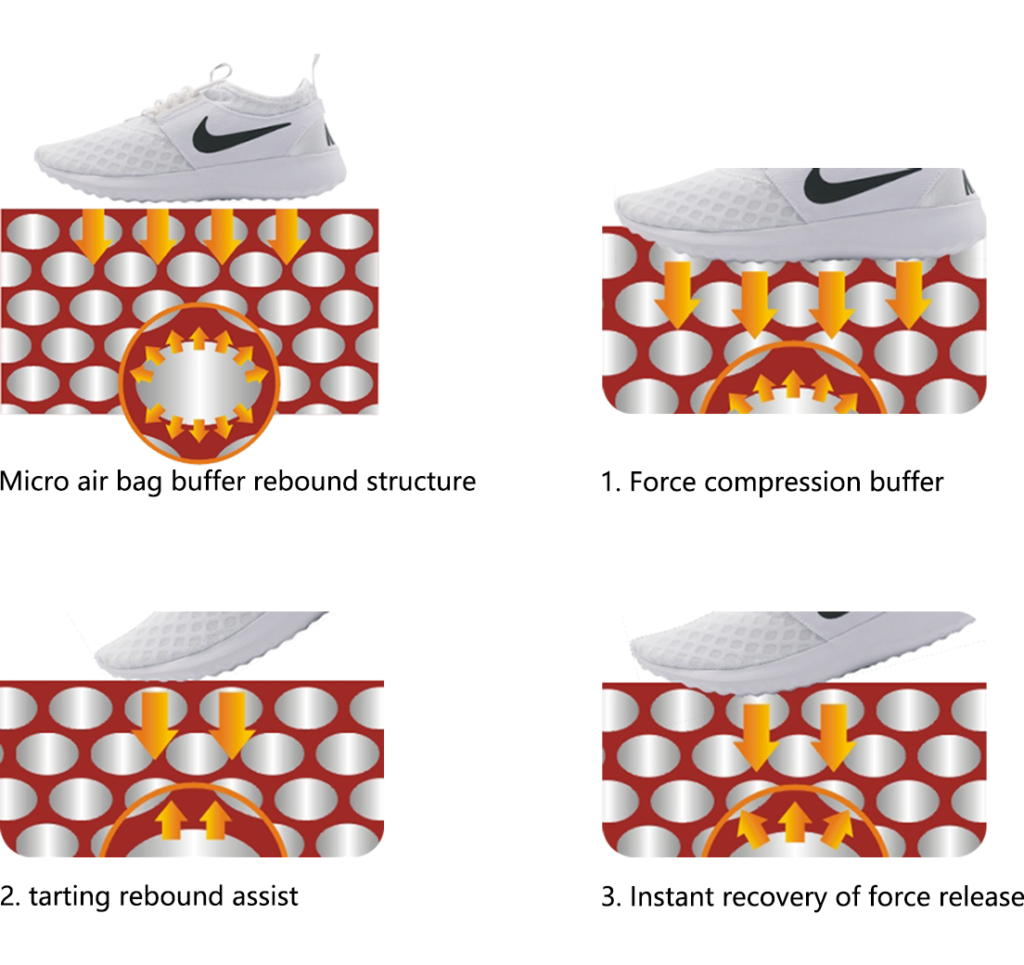

Si-PU Sports Physical Characteristics

Designed with ergonomic principles and tailored to the physical demands of sports, our Si-PU system features a hard top layer and an elastic bottom layer. This professional, health-focused synthetic court surface can be directly applied to cement or asphalt. Named “Si-PU” for its single-component silicone-modified polyurethane buffering and rebounding structure.

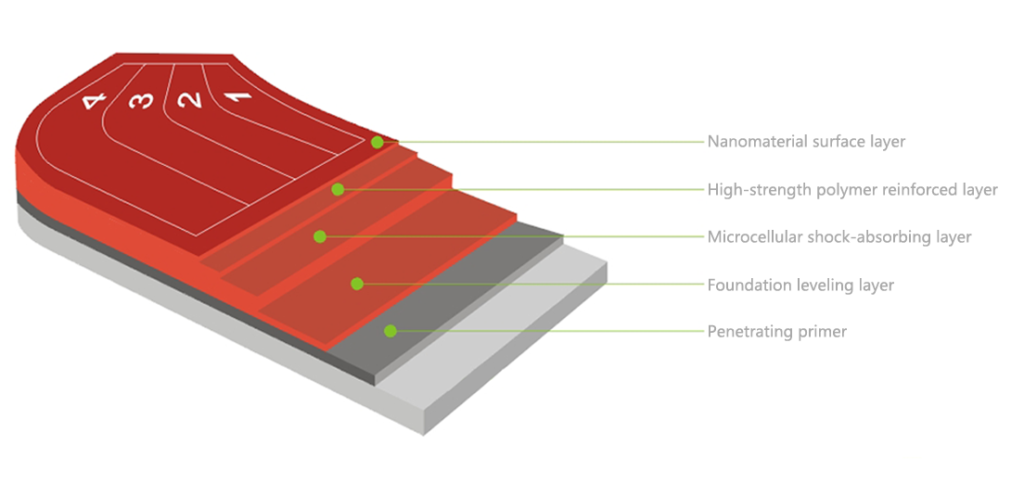

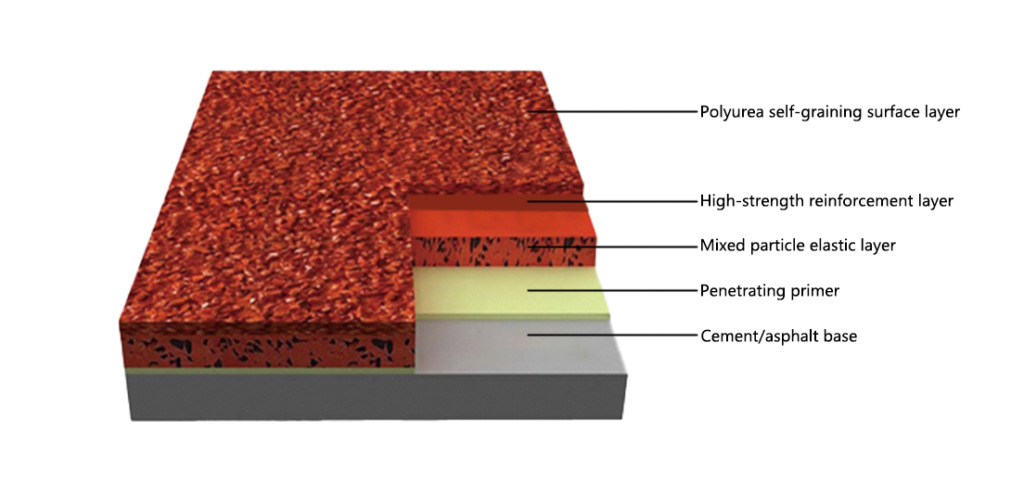

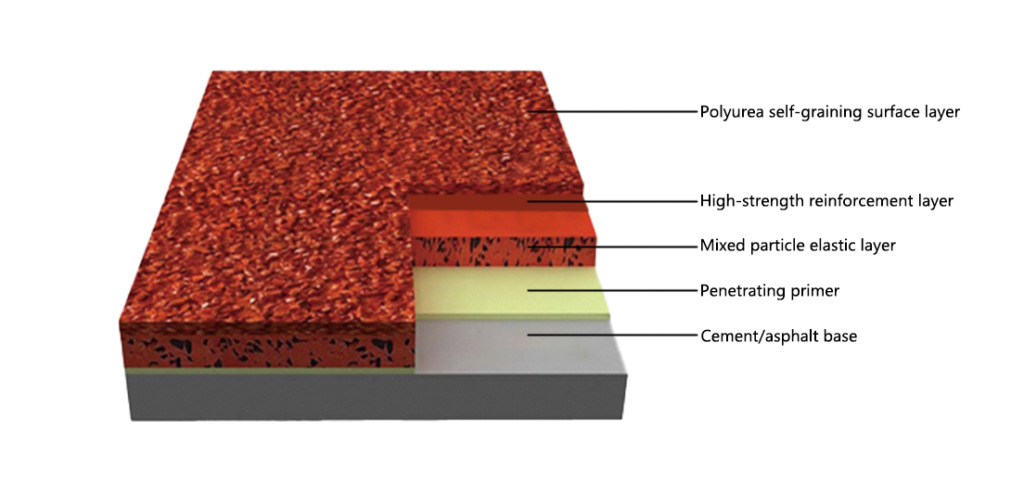

Si-PU Running Track Structure

- Polyurea self-textured surface layer

- High-strength reinforcement layer

- Mixed particle elastic layer

- Penetrating

- Cement/asphalt base

Micro air bag buffer rebound structure

Provide the most reasonable protection and professional economic assistance for sports

- 1. Force compression buffer

- 2. Starting rebound assist

- 3. Instant recovery of force release

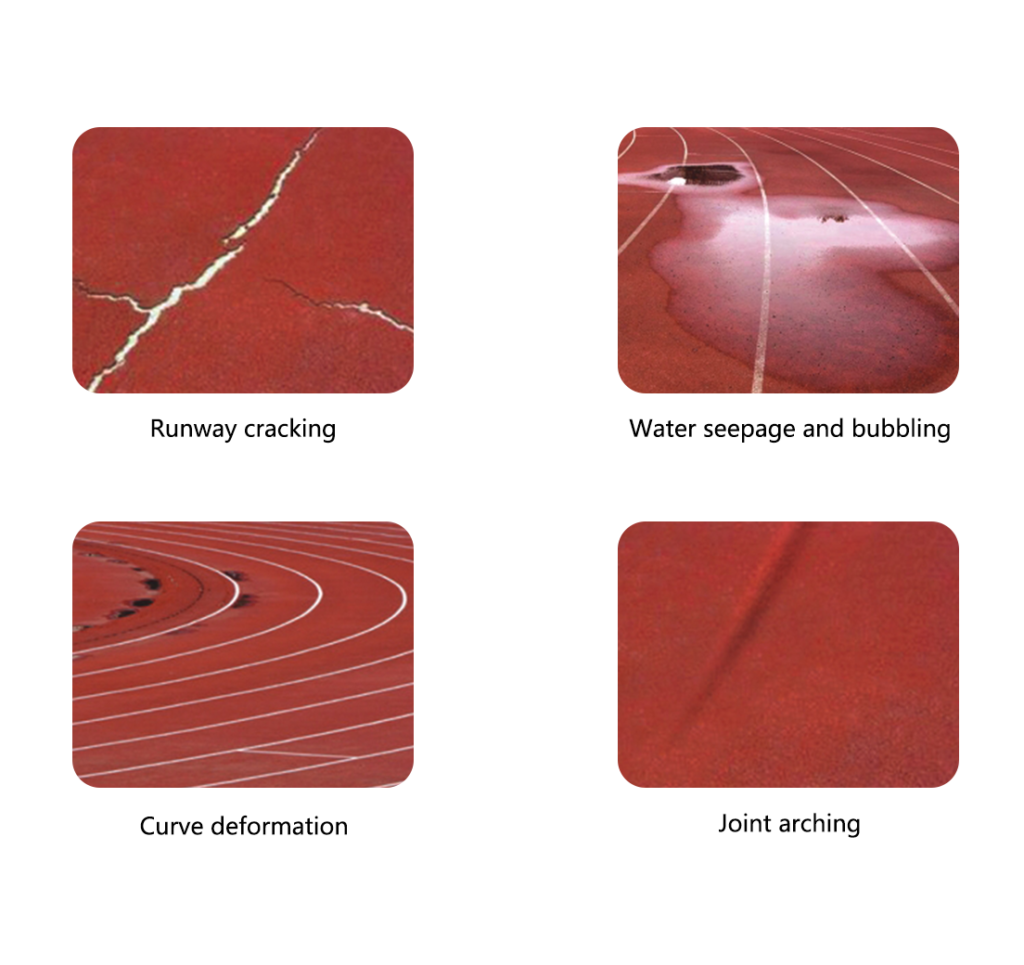

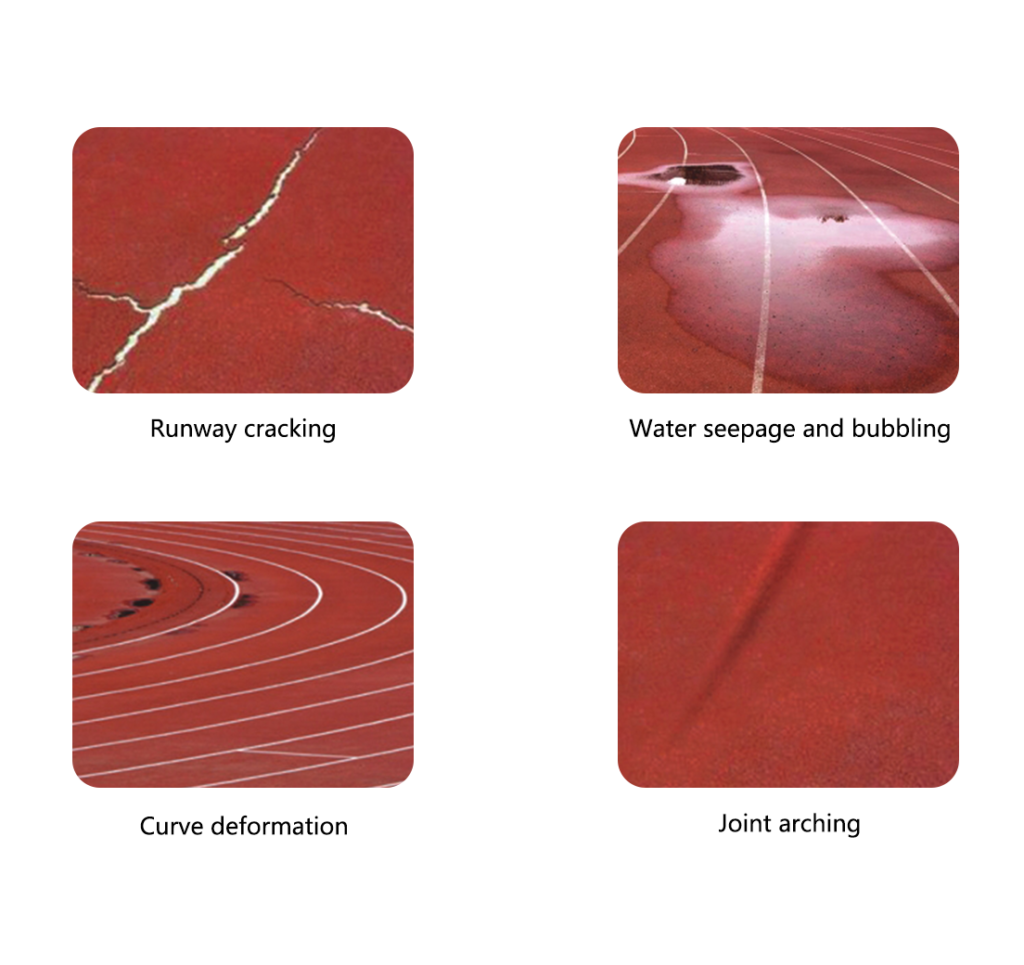

Seamless sports field structure

Comprehensively solve the quality problems caused by the seams of rolled products.

Adopt an integrated seamless forming process, which can achieve secondary leveling of the site, ensuring the smoothness and uniformity of the track; the fully enclosed seamless structure effectively prevents external rainwater from infiltrating the track, causing deformation of curves, seam cracking and lifting, water seepage, or bubbling and other quality issues.

Non-toxic and odorless material

From raw materials to finished products, we measure with smell and make the impossible possible

- Certification Compliance

Our si-PU products meet EU RoHS and CE certifications, ensuring international quality standards. - Advanced Material Selection

We use scientifically selected anti-aging polymer materials combined with advanced anti-aging agents to enhance durability and stability. - Innovative Technology

Our products incorporate micro-capsule nano technology, providing deep integration and extended longevity. - Safety Assurance

Free from harmful substances such as phthalates, chlorinated paraffins, MOCA, TDI, benzene substances, polycyclic aromatic hydrocarbons (PAHs), and heavy metals, ensuring safety and environmental friendliness. - Low Emissions

With a TVOC content of just 0.1, our products fully comply with the latest international standards, promoting a healthier environment.

| Fully plastic self-tie | |||

|---|---|---|---|

| 1k Full Plastic Self-Knot Pattern Track 13mm | 2k Full Plastic Self-Knot Pattern Track 13mm | ||

| Material Type | Usage Kg/m² | Material Type | Usage Kg/m² |

| P01V Cement Primer | 0.2 | P01V Cement Primer | 0.2 |

| Running Track Elastic Layer CP02-X | 10.8 | Elastic Layer CP02-P (5:1) | 11 |

| Running Track Self-Knot Surface Layer CP05 | 1.5 | Running Track Self-Knot Surface Layer CP05 | 1.5 |

| Auxiliary (02-0.05) | 0.54 | Auxiliary (02-0.05) | 0.22 |

| Full plastic grain surface | |||||

|---|---|---|---|---|---|

| 1k Full Plastic Granular Surface Track (13mm) | 2k Full Plastic Granular Surface Track (13mm) | ||||

| Material Type | Usage Kg/m² | Material Type | Usage Kg/m² | ||

| Primer | Polyurethane Primer P01V | 0.2 | Primer | Polyurethane Primer P01V | 0.2 |

| Elastic Layer | Elastic Layer CP02-X | 9 | Elastic Layer | Elastic Layer CP02-P (5:1) | 9.5 |

| Spraying Surface | Surface Layer CP04 | 1.1 | Spraying Surface | Surface Layer CP04 | 1.1 |

| 20% EPDM Granules (1-3) Red/Green | 1.1 | 20% EPDM Granules (1-3) Red/Green | 1.1 | ||

| Auxiliary (02-0.05) | 0.45 | Auxiliary (02-0.05) | 0.19 | ||

PU Hybrid Track

Si-PU Sports Physical Characteristics

The MPU eco-friendly hybrid plastic track features a base layer made of PU slurry mixed with EPDM granules, and a surface layer sprayed with a blend of specialized surface adhesive and EPDM granules. This type of track offers a comfortable level of elasticity, effectively reducing physical exertion. The highly resilient cushioning layer absorbs powerful impacts, significantly minimizing the risk of sports injuries.

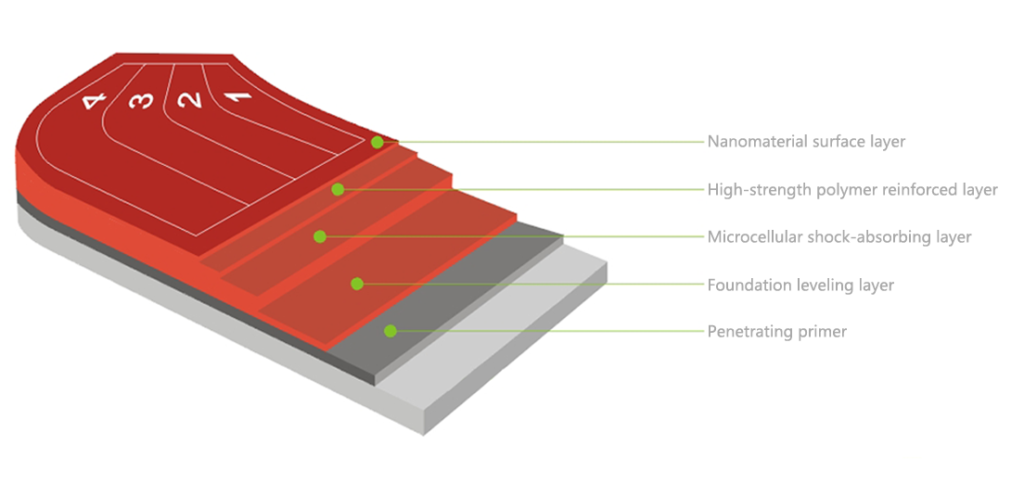

Si-PU Running Track Structure

- Nanomaterial surface layer

- High-strength polymer reinforced layer

- Microcellular shock-absorbing layer

- Foundation leveling layer

- Penetrating primer

Construction Process

1. Foundation treatment

2. Primer sealing construction

3. Scrape and apply mixed particle elastic layer

4. Scrape and apply reinforcement layer

5. Spray surface construction

6. Marking

| Mixed self-tie | |||||

|---|---|---|---|---|---|

| 1K | 13mm Composite Self-texturing Track | 2K | 13mm Composite Self-texturing Track | ||

| Material Type | Usage Kg/m² | Material Type | Usage Kg/m² | ||

| Cement Primer | Polyurethane Primer SW01 | 0.2 | Cement Primer | Polyurethane Primer SW01 | 0.2 |

| Elastic Layer | Elastic Layer CP02-X | 7 | Elastic Layer | Elastic Layer CP02-P (5:1) | 8 |

| EPDM Bottom Granules | 2.5 | EPDM Bottom Granules | 2.5 | ||

| Elastic Layer CP02-X | 2 | Elastic Layer CP02-P (5:1) | 1.5 | ||

| Auxiliary (02-0.05) | 0.54 | Auxiliary (02-0.05) | 0.285 | ||

| Spraying Surface | Surface Layer (Self-Knot) CP05 | 1.5 | Spraying Surface | Surface Layer (Self-Knot) CP05 | 1.5 |

| Mixed particle surface | |||||

|---|---|---|---|---|---|

| 1K | 13mm Mixed Type/Granular Surface Track | 2K | 13mm Mixed Type/Granular Surface Track | ||

| Material Type | Usage Kg/m² | Material Type | sage Kg/m² | ||

| Primer | Polyurethane Primer SW01 | 0.2 | Primer | Polyurethane Primer SW01 | 0.2 |

| Elastic Layer | Running Track Elastic Layer CP02X | 7 | Elastic Layer | Elastic Layer CP02-P (5:1) | 7.5 |

| Bottom Granules | 3 | Bottom Granules | 3 | ||

| Spraying Surface | Surface Layer (Granular) CP04 | 1.1 | Spraying Surface | Surface Layer (Granular) CP04 | 1.1 |

| Spraying Granules | 1.1 | Spraying Granules | 1.1 | ||

| Auxiliary (02-0.05) | 0.42 | Auxiliary (02-0.05) | 0.225 | ||

Quality Management System

Features of Silicone Polyurethane

Silicone polyurethane is a hybrid polymer material that combines the properties of silicone and polyurethane, resulting in a flexible, durable, and chemically resistant material suitable for a variety of industrial and commercial applications.

The primary benefits include high flexibility, excellent durability, superior chemical and weather resistance, thermal stability, and biocompatibility.

Silicone polyurethane is commonly used in industries such as medical devices, textiles, automotive, electronics, construction, and sports surfaces.

It provides a resilient, shock-absorbent surface that reduces impact on athletes, enhances traction, and maintains stability under various weather conditions, leading to improved performance and reduced injury risks.

Yes, silicone polyurethane is considered environmentally friendly due to its durability and long lifespan, which reduce the need for frequent replacements and minimize waste.

Yes, silicone polyurethane can be tailored to meet specific application requirements, available in various forms such as coatings, adhesives, and molded parts.

Its biocompatibility, non-toxicity, flexibility, and resistance to chemicals and sterilization processes make it ideal for medical applications such as catheters, tubing, and implants.

Silicone polyurethane requires less maintenance due to its high durability, resistance to wear and tear, and ease of cleaning, leading to lower long-term maintenance costs.

Running tracks, football fields, and basketball courts can benefit from silicone polyurethane due to its shock absorption, traction, weather resistance, and consistent performance characteristics.

Yes, silicone polyurethane exhibits excellent resistance to UV radiation, making it suitable for outdoor applications where prolonged sun exposure is a concern.

Looking for a Material Safety Data Sheet? (MSDS / SDS) Click the link to complete a request form.