Polyurea Paint

Polyurea: Ultimate corrosion protection for industrial durability.

Your trusted supplier of polyurea paint

MPU produces a range of advanced polyurea paint and linings, including pure polyurea, polyurethane, polyurea-polyurethane hybrids, polyaspartic aliphatic polyurea, and primers. Each product is formulated for specific applications。 Our polyurea coatings provide long-lasting protection against rust, corrosion, and wear, even in the most demanding conditions, requiring minimal maintenance.

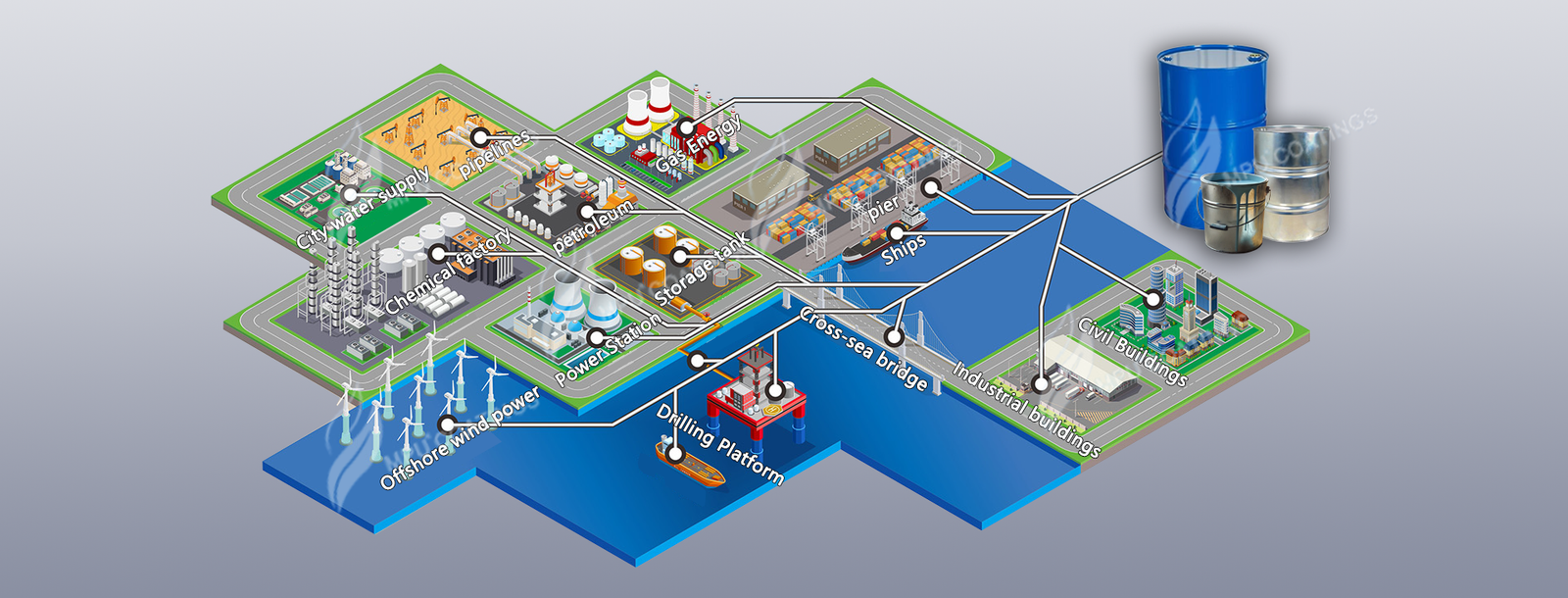

Explore MPU’s polyurea paint, engineered to protect infrastructure, chemical tanks, pipelines, and marine assets from corrosion and damage. Ideal for power plants, bridges, and marine engineering, it ensures long-term durability, reducing maintenance needs and prolonging investment lifespan.

In transportation, MPU’s polyurea coatings provide superior corrosion resistance, durability and durability for vehicles such as trucks, trains, airplanes, yachts and ships. Our polyurea paint can be sprayed, rolled, or brushed, offering flexible application options. We also provide custom paints tailored for OEM/ODM, adaptable to your brand, color, and packaging requirements.

Application Scenario

Pipeline & Chemical Storage Tanks

• Longevity & Durability: Polyurea and polyurethane paint protect pipelines from weathering and corrosion with strong physical properties.

• Corrosion Prevention: This paint prevents material failure by separating the environment and transport fluids from pipeline materials.

• Environmental & Safety Assurance: Polyurea paint is solvent-free, VOC-free, and helps prevent environmental damage and ensure safe operations.

• Efficiency & Compliance: It enhances flow efficiency, reduces friction, and ensures pipelines meet safety regulations.

Petroleum Industry

Protection and Longevity

Polyurea paint provides superior protection for oil and gas storage tanks, containers, and pipelines against abrasion, weather, and chemical corrosion. It extends the lifespan of these assets, ensuring durability and reliability in harsh environments.Weather Resistance

Polyurea forms a resilient membrane that withstands extreme weather conditions, including snow, ice, rain, and UV exposure. It is ideal for protecting exterior surfaces, reducing maintenance needs, and ensuring long-term performance.Enhanced Safety and Performance

With strong physical and elastomeric properties, polyurea paint is the preferred choice for primary and secondary containment in storage tanks. It prevents chemical leaks, protects workers, and reduces the risk of explosions, thereby upholding safety standards in the petroleum industry.

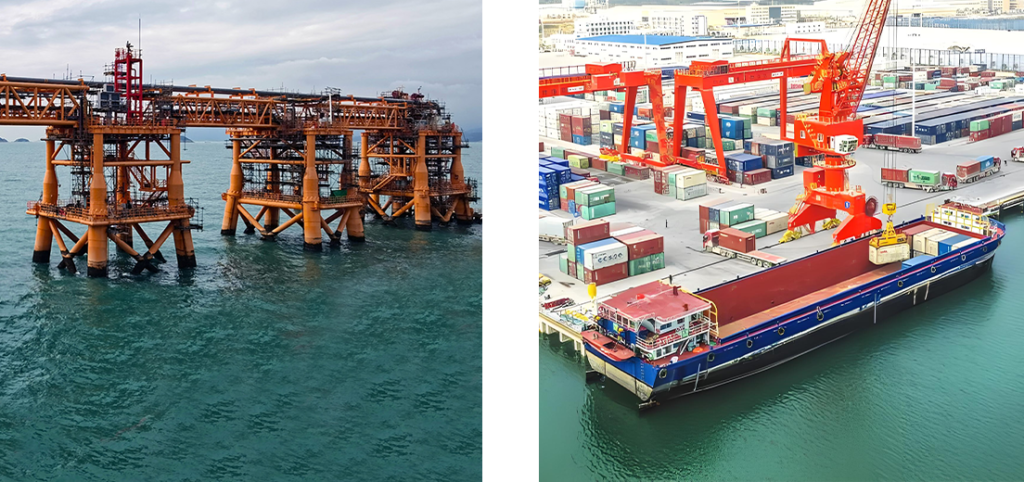

Marine Engineering

Dock Protection

Polyurea paint is widely used to protect the concrete and steel structures of docks. It prevents seawater erosion, mechanical wear, and chemical corrosion, thereby extending the lifespan of the docks.

Offshore Platform Protection

In offshore oil and gas extraction, polyurea paint is applied to protect the decks, pipelines, and other metal structures of offshore platforms. It helps prevent corrosion and wear, ensuring the safe operation of the platforms.

Anti-Slip Paint

In working areas of docks and offshore platforms, polyurea paint can be applied as an anti-slip coating. This reduces the risk of slips and falls for workers in wet environments, enhancing operational safety.

Leak Prevention

Polyurea paint has excellent waterproof properties, preventing seawater from penetrating the internal structures of docks and offshore platforms. This protects internal equipment and structures from corrosion and damage.

Ships

Polyurea paint is increasingly utilized in the maritime industry due to its exceptional protective properties and ability to withstand harsh marine environments.

Hull and Deck ProtectionPolyurea coatings are widely used for protecting the hull and decks of ships, providing resistance against seawater, wind, and other external factors. They effectively safeguard the internal compartments during cargo transport, preventing moisture and contaminants from entering.

Interior and Storage AreasPolyurea coatings can protect the interior and storage areas of ships, ensuring that transported goods (such as liquids and food) are not affected by external environments. This coating prevents wear and corrosion, maintaining the freshness and safety of the cargo.

Anti-Slip CoatingsOn ship decks and other working areas, polyurea coatings can incorporate anti-slip technology, reducing the risk of slips and falls on wet surfaces. This provides a safer working environment for crew members operating on the water.

Equipment ProtectionPolyurea coatings can also protect onboard equipment from moisture and chemical exposure. By providing a protective layer for equipment, the lifespan is extended, and maintenance costs are reduced.

Water Application

• Optimal Service Life: MPU Polyurea Paint ensures long-lasting protection for equipment and facilities handling various water applications, including drinking water, stormwater, and wastewater.

• Versatile Application: Suitable for both renovation of existing structures and new construction, ensuring durability under high wear and chemical exposure.

• Comprehensive Coverage: Protects systems involved in stormwater collection, drinking water distribution, domestic sewage treatment, and industrial wastewater management.

• Specialized Solutions: Ideal for use in desalination processing, storage, and distribution systems.

Infrastructure

• Durability & Protection: Provides long-lasting protection against wear, chemicals, saltwater, impact, and UV exposure.

• Customized Solutions: Polyurea paint is tailored to meet infrastructure demands, offering enhanced performance in varied conditions.

• Versatile Applications: Ideal for tunnels, bridges, and transportation systems, including heavy and light rail.

• Comprehensive & Cost-Effective: Delivers economical, complete, and rapid solutions with an extended design life.

Mining & Metals

• Applications: Suitable for both maintenance and new construction projects across various mineral extraction operations.

• Durability & Protection: Polyurea paint provides high wear and chemical resistance, ensuring long-term protection in mining processes.

• Comprehensive Coverage: Protects process liners, distribution liners, containment liners, and pipe linings in harsh mining environments.

• Specialized Coatings: Ideal for sulfide flotation cells, settling tanks, and other critical mining equipment.

Polyurea paint construction scheme

Spray Paint

Surface Preparation

- Proper preparation ensures good adhesion and long-term performance of polyurea paint.

- Surfaces must be clean, dry, and free of contaminants like oil, grease, and rust.

- Abrasive blasting is often used for the desired surface profile and cleanliness.

- A primer may be used on some substrates for better adhesion.

Spraying Method

- Polyurea paint is applied with specialized spray equipment.

- Creates a seamless, uniform coating on complex surfaces.

Dosage and Thickness

- Typically applied at 30-100 mils (0.75-2.5 mm) for corrosion protection.

- Thickness depends on application needs and service conditions.

- 60-100 mils for secondary containment, 30-60 mils for truck bed liners.

- High build properties allow single-pass application.

Roller Painting

Surface Preparation

- Proper surface preparation is essential for good adhesion and performance of roller-applied polyurea paint.

- Surfaces must be clean, dry, and free of contaminants like oil, grease, and rust.

- Abrasive blasting or grinding is often used to achieve the required surface profile and cleanliness.

- A primer may be used on some substrates to enhance adhesion.

Application Method

- MPU Polyurea roller paint is a series of products with diverse performance, consisting of polyaspartic acid ester resins or other amino compounds, and bio-based polyol resins, used with UV-resistant aliphatic modified curing agents.

- Components are mixed and applied with a roller, similar to regular paint.

- Rollers are ideal for smaller areas or where spray equipment isn’t practical.

Dosage and Thickness

- Typically applied at 10-20 mils (250-500 μm) per coat.

- Multiple coats may be required, with full curing between applications.

- Thickness depends on application requirements and service conditions.

Application Scenarios

Looking for a Material Safety Data Sheet? (MSDS / SDS) Click the link to complete a request form.

Polyurea is an elastomer derived from step-growth polymerization, which involves combining a synthetic resin and an isocyanate reactive material. It is renowned for its rapid curing time, durability, and resistance to various environmental factors.

Polyurea is used in a wide range of applications including waterproofing, coatings for pipelines, secondary containment, tank linings, flooring, and protective coatings for concrete and steel structures.

Polyurea offers superior benefits such as faster curing times, greater flexibility, excellent abrasion resistance, and strong chemical resistance compared to traditional materials like epoxy and polyurethane.

Polyurea coatings provide outstanding durability, resistance to chemicals and abrasions, waterproofing capabilities, quick application and curing times, and the ability to adhere to a variety of substrates.

Yes, polyurea can be applied in a wide range of temperatures, from sub-zero to high heat environments, making it versatile for various climatic conditions.

Polyurea has an exceptionally fast curing time, typically ranging from seconds to minutes, allowing for quick project turnaround and minimal downtime.

Polyurea is environmentally friendly as it contains no volatile organic compounds (VOCs), solvents, or other hazardous substances, making it safe for use in sensitive environments.

Polyurea can be applied to numerous surfaces including concrete, steel, wood, and other metals, as well as various types of plastics and foam.

The longevity of a polyurea coating depends on the specific application and environmental conditions but typically, polyurea coatings can last for many years, providing long-term protection and performance.

Polyurea coatings require minimal maintenance. Regular cleaning and periodic inspections for any signs of wear or damage will help ensure the longevity and performance of the coating.