Polyaspartic Resin

MPU specializes in polyaspartic resins, amine compounds, and latent curing technology.

Your Trusted Supplier Of Polyaspartic Resin

Polyaspartic polyurea material is an innovative aliphatic, slow-reacting, high-performance coating in the polyurea industry, known as the third generation of polyurea.

MPU specializes in polyaspartic resins, amine compounds, and latent curing technology. After years of product development, we have launched a cost-effective series of polyaspartic resins and amine compounds to meet various application needs. Our products are used in wind and hydropower anti-corrosion, flooring, exterior walls, civil waterproofing, furniture, and automotive industries.

We offer OEM/ODM services, customizing packaging to match your brand colors. With our chemical expertise, we are confident in delivering solutions that exceed your expectations.

Definition of Polyaspartic Resin

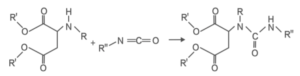

Polyaspartic resin is an advanced high-performance material classified under polyurea resins, derived from the reaction between an aliphatic polyisocyanate and a polyaspartic ester, an aliphatic diamine. This advanced polymer technology is renowned for its unique properties, high performance, and versatility, making it highly popular in various applications, especially within the coatings industry.

Features of Polyaspartic Resin

This product is a solvent-free resin with secondary amino groups that can react with -NCO.

1. High solid content and low viscosity, suitable for formulating high solid content, low viscosity, environmentally friendly coatings (with a solid content up to 100% during application).

2. The coating film exhibits excellent fullness, leveling properties, and gloss.

3. The coating also has outstanding weather resistance, water resistance, solvent resistance, acid and alkali resistance, and salt spray resistance.

4. High hardness (up to 3-4H) with particularly notable abrasion resistance [abrasion loss ≤ 20mg (500r/750g)]. Adding Abrasion-Resistant Polyurea, hardness can reach 6H

5. Excellent adhesion to plastics such as ABS, PC, PVC, and various metals.

Properties of Polyaspartic Resin

- Fast Cure Time: Polyaspartic coatings cure much faster than traditional epoxies and polyurethanes, allowing for rapid return-to-service times, often within a few hours

- UV Stability: They are UV stable, meaning they do not yellow or degrade when exposed to sunlight, maintaining their appearance and performance over time

- Durability: Polyaspartic coatings are highly resistant to abrasion, scratches, and chemical spills, making them suitable for high-traffic and industrial environments

- Flexibility: They can be formulated to be flexible, allowing them to bridge small cracks and be applied on various substrates such as concrete, wood, and metal

- Low VOCs: These coatings can be formulated with low volatile organic compounds (VOCs), making them environmentally friendly and suitable for indoor applications

Advantages of Polyaspartic Resin

- One-Coat Application: They can be applied in thicker layers (up to 16-18 mils) in a single coat, reducing labor and material costs

- Rapid Curing: The fast curing time allows for quick project turnaround, reducing downtime for facilities

- Weatherability: Their UV stability and resistance to yellowing make them ideal for outdoor applications

- Toughness: They form hard, abrasion-resistant films that withstand heavy wear and tear

- Chemical Resistance: Polyaspartic coatings resist many chemicals, making them suitable for industrial and laboratory environments.

- Application Flexibility: They can be applied at a wide range of temperatures and humidity levels, offering versatility in different climates

Applications of Polyaspartic Resin

| Polyaspartic Resin | ||||||

|---|---|---|---|---|---|---|

| Name/Item | Appearance | Molecular Weight | Viscosity mps/25℃ | NH Equivalent g/mol | Relative Density | Flash Point ℃ |

| M-1520 | Light yellow transparent liquid | 582 | 900~1300 | 291 | 1.06±0.02 | 90~95 |

| M-1420 | Light yellow transparent liquid | 554 | 900~1300 | 277 | 1.06±0.02 | 90~95 |

| M-1220 | Light yellow transparent liquid | 472 | 60~100 | 230 | 1.06±0.02 | 90~95 |

Product Usage

- Can be used as a protective topcoat in heavy and light anti-corrosion fields such as industrial flooring, steel structures, and oil pipelines.

- Applied in high-end coatings such as automotive paint and wood coatings to enhance film fullness, gloss, hardness, and accelerate curing speed.

- Suitable for foam landscapes, concrete waterproofing materials, and similar applications.

- Utilized in wind turbine blade coatings, including gel coats, putty, and topcoats.

- Applicable in municipal engineering for highway bridges and outdoor landscaping facilities.

| Polyaspartic Resin | ||||||||

|---|---|---|---|---|---|---|---|---|

| Name/Item | Molecular Weight | Appearance | Solid Content | Amine value(mg KOH/g) | Amine Equivalent(g/mol) | Viscosity mpa.s/25°C | Relative density(25°C) | Flash Point(°C) |

| M-2420 | 554 | Colorless transparent liquid | 97%±2% | 199-203 | 277 | 900-1300 | 1.06±0.02 | 97 |

Product Usage

- Concrete Flooring: Ideal for garage floors, commercial kitchens, and retail stores due to their durability and ease of maintenance

- Industrial Coatings: Used for protecting steel structures from corrosion and abrasion in industrial settings

- Wood and Plastic Coatings: Suitable for flexible substrates, providing a tough, protective layer

- Wind Turbines and Composites: Applied in the renewable energy sector for their weather resistance and durability

- Medical and Laboratory Floors: Their chemical resistance and ease of cleaning make them suitable for hospitals and laboratories

| Polyaspartic Resin | ||||||||

|---|---|---|---|---|---|---|---|---|

| Name/Item | Molecular Weight | Appearance | Solid Content | Amine value(mg KOH/g) | Moisture content% | Viscosity mpa.s/25°C | Relative density(25°C) | Flash Point(°C) |

| M-2520 | 582 | Slight yellow transparent liquid | 96%±2% | 189-193 | ≤0.05 | 900~1300 | 1.06±0.02 | 97 |

Product Usage

Widely applicable in high-end industrial paints and wood coatings, especially suitable for scenarios requiring high hardness and high wear resistance. It can be used to formulate high-end solid wood color wipes.

Suitable for topcoats in heavy and light anti-corrosion coatings, such as those used on steel structures and petroleum pipelines.

Applicable in the field of wind turbine blade coatings, including gel coats, putties, and topcoats for wind turbine blades.

Widely used in automotive paints, significantly improving the film fullness, gloss, hardness, and accelerating the curing process.

Due to its 100% solid content, low viscosity, good wetting, and broad compatibility, this resin is widely used for grinding high-concentration color pastes. It is particularly suitable for grinding high-concentration universal color pastes in automotive refinish coatings. The white paste produced with this resin can reach 100% solid content, with titanium dioxide content up to approximately 70%. It is also very suitable for grinding high-pigment carbon black, providing better blackness compared to ordinary acrylics.

PACKING

PACKING

- 200 Kgs/Drum, 10 Kgs/Drum

SHELF LIFE

- FEISPARTIC F520 must be stored in airtight containers to prevent contact with moisture. Recommended storage temperature is below 40°C (≤104°F). The shelf life of FEISPARTIC F520 in the original closed container is 12 months.

NOTICE

- FEISPARTIC F520 is combustible and should be stored below 40 ℃. It should be kept away from fire source and stored in a cool, dry, and ventilated environment. The storage period is 12 months.

- The coating formulated with FEISPARTIC F520 should be tested for performance after one week’s maintenance.

Note: This manual is for reference only, without any warranty. In view of the limitation of resin function and the diversity of user requirements, please strictly test the adaptability of the product and the stability of the final product. The technical information is subject to change without prior notice.

Frequently Asked Questions (FAQ)

Polyaspartic resin is an aliphatic polyurea derived from the reaction of an aliphatic polyisocyanate with a polyaspartic ester. It is known for its rapid curing time, durability, and versatility in various coating applications.

The primary benefits include:

- Rapid curing time

- High durability and abrasion resistance

- Chemical and UV resistance

- Flexibility and impact resistance

- Low VOC emissions

- Clear and high-gloss finishes

Polyaspartic resin cures much faster than epoxy, reducing project downtime. It offers better UV stability, preventing yellowing, and provides superior chemical and abrasion resistance. Additionally, polyaspartic coatings can be applied in varying thicknesses without bubbling.

Polyaspartic resin can be applied to various substrates, including concrete, metal, wood, and existing coatings. Its versatility makes it suitable for industrial floors, commercial spaces, and residential applications.

Yes, polyaspartic resin typically has low VOC (volatile organic compounds) emissions, making it a more environmentally friendly option compared to many traditional coatings.

Polyaspartic resin cures rapidly, often within a few hours. This fast curing time allows for a quicker return to service, reducing downtime for industrial and commercial applications.

Yes, polyaspartic resin is highly resistant to UV radiation and weather conditions, making it suitable for outdoor applications. It maintains its clarity and durability even in harsh environmental conditions.

Polyaspartic resin coatings are low maintenance. Regular cleaning with mild detergents is usually sufficient. Their smooth, non-porous surface resists staining and makes cleaning easy.

While polyaspartic resin has many advantages, it requires careful handling during application due to its rapid curing time. Proper surface preparation is also essential to ensure optimal adhesion and performance.

Yes, polyaspartic resin formulations can be tailored to meet specific performance requirements. Customization options include varying the thickness, color, and other properties to suit different industrial, commercial, and decorative needs.

Looking for a Material Safety Data Sheet? (MSDS / SDS) Click the link to complete a request form.