Pipeline Coatings Solutions

Polyurea coatings deliver seamless coverage, corrosion resistance, durability, and lasting protection for pipes

Your trusted supplier of Pipeline polyurea coatings

MPU specializes in delivering premium, environmentally-friendly protective coatings for pipe systems in demanding industries. Our polyurea coatings are rigorously tested to ensure superior performance in corrosion resistance, waterproofing, and temperature tolerance, meeting the specific needs of oil and gas pipelines, industrial facilities, water and wastewater systems, and HVAC manufacturers. These coatings provide a seamless, durable layer of protection, effectively preventing rust, leaks, and damage caused by extreme environments. Designed for long-term performance, our coatings help extend the service life of pipes while minimizing maintenance costs.

We offer OEM/ODM services tailored to your unique requirements. Whether you need custom formulations, color matching, specialized packaging, or application-specific solutions, MPU coatings are engineered to address your toughest challenges. By choosing MPU, you gain advanced protection that enhances operational efficiency and ensures compliance with environmental standards. Contact us today to explore how our coatings can safeguard your pipes and elevate your infrastructure.

Why Choose Polyurea Coatings to Protect Pipeline?

Advantages of polyurea for pipes

1,Seamless Coverage, 100% Waterproof

2,Fast Curing, High Construction Efficiency

3,Chemical Resistance, Scratch Resistance, & High-Temperature Durability

Pipeline Polyurea Application Areas

1,Oil and Gas Pipelines

2,Industrial sewage Pipelines

3,Chemical and Pharmaceutical Factory Pipelines

Pipeline Polyurea Application Areas

| Parameter | Value/Range | Description |

|---|---|---|

| Coating System | Primer + Spray Polyurea | Ensures strong substrate bonding with the primer layer and seamless, durable protection with the spray-applied polyurea topcoat. |

| Coating Thickness | 1.8–3.2 mm (including primer) | Includes both the primer layer and polyurea topcoat for optimal protection. |

| Corrosion Resistance | ≥ 1200 hours (ASTM B117 Salt Spray Test) | Primer enhances adhesion to the substrate, while polyurea provides long-lasting corrosion resistance. |

| Operating Temperature | -45°C to +130°C | Primer stabilizes the surface for performance under extreme conditions, complemented by the polyurea’s thermal stability. |

| Abrasion Resistance | ≤ 45 mg loss (ASTM D4060, CS-17, 1000 cycles) | The polyurea topcoat offers exceptional resistance to mechanical wear, protecting the pipe surface in high-pressure environments. |

| Adhesion Strength | ≥ 12 MPa (ASTM D4541 Pull-Off Test) | Primer significantly enhances the adhesion strength to metal or concrete substrates. |

| Elongation at Break | 250%–450% | Flexibility of the polyurea layer ensures durability against movements or pressure changes in pipes. |

| Hardness (Shore D) | 42–62 | The combination of primer and polyurea provides a robust yet elastic system for comprehensive protection. |

| Water Absorption | ≤ 0.3% (ASTM D570) | Primer creates a base layer with minimal water penetration, while polyurea ensures superior waterproofing. |

| UV Resistance | No chalking or discoloration (600 hours, QUV) | The topcoat resists UV degradation, ideal for pipelines exposed to sunlight. |

| Chemical Resistance | Resistant to strong acids, alkalis, and hydrocarbons | The primer and polyurea layers together provide maximum chemical protection for pipelines. |

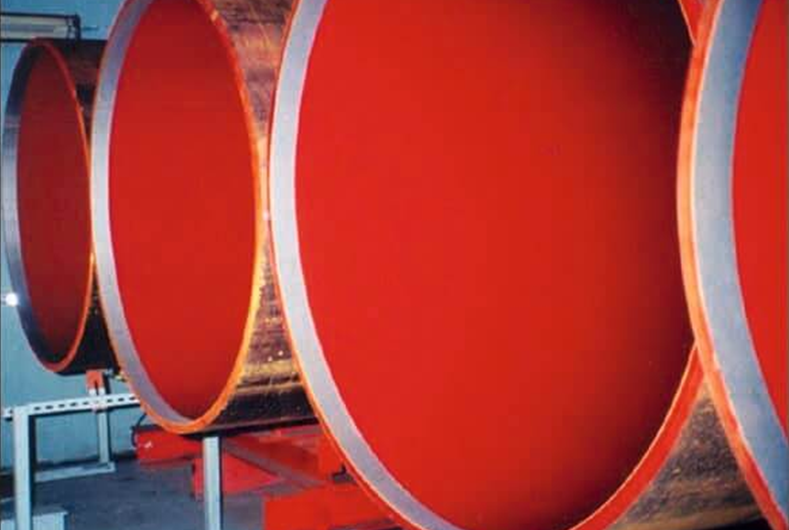

Product display

FAQ

What is polyurea?

Polyurea is an elastomer derived from step-growth polymerization, which involves combining a synthetic resin and an isocyanate reactive material. It is renowned for its rapid curing time, durability, and resistance to various environmental factors.

What types of pipelines are suitable for polyurea coatings?

Polyurea coatings are suitable for a wide range of pipelines, including:

- Oil and gas pipelines: Protection against corrosion, chemicals, and abrasion in harsh environments.

- Water pipelines: Seamless waterproofing to prevent leaks and contamination.

- Industrial pipelines: Resistance to chemicals, high pressure, and extreme temperatures.

- Underground pipelines: Long-term protection against soil corrosion and groundwater ingress.