industrial floor coatings

Polyurea coatings are the best industrial floor paint for concrete, offering superior abrasion-resistant coating that enhances the durability and longevity of concrete floor coatings.

Your trusted industrial floor coatings suppliers

Discover MPU COATINGS’ third-generation polyurea coatings, the best industrial floor paint for concrete with superior durability, abrasion resistance, and UV protection. Compared to traditional industrial floor coatings, our advanced solution is designed to outperform in every aspect. Specializing in polyaspartic acid, amine compounds, and latent curing technology, MPU COATINGS provides an abrasion-resistant coating that ensures long-term performance and reliability.

Our innovative self-leveling polyurea simplifies application by eliminating the need for a topcoat, significantly enhancing efficiency. Tailored for OEM/ODM, our custom coatings can be adapted to your specific brand, color, packaging, and application requirements, making them an ideal choice for industrial floor paint suppliers.

Rely on our chemical expertise to deliver concrete floor coatings that set new standards in performance and longevity. MPU COATINGS offers a comprehensive range of protective and waterproof solutions, ideal for industrial applications. Whether you need a basic protective layer or fully structural coatings, our products provide exceptional protection against corrosion, decay, erosion, extreme temperatures, and abrasion.

What kind of industrial floor coatings?

Common Industrial floor coatings include: Epoxy Floor Coatings, Polyurethane Floor Coatings, Polyurea Floor Coatings, Acrylic Floor Coatings, and Cementitious Urethane Coatings.

1,Polyurea Floor Coatings

- Characteristics: Polyurea coatings are known for their exceptional impact and chemical resistance.

- Applications: Industrial warehouses, manufacturing plants, and environments with extreme conditions (e.g., heavy machinery).

- Benefits: high flexibility, abrasion resistance, and waterproofing.

2,Polyurethane Floor Coatings

- Characteristics: Polyurethane coatings offer excellent abrasion resistance and can withstand harsh chemicals and UV exposure. They tend to be more flexible than epoxy coatings.

- Applications: Automotive shops, pharmaceutical facilities, and areas requiring UV protection (such as outdoor spaces or sun-exposed floors).

- Benefits: Enhanced flexibility, abrasion resistance, and UV stability.

3,Epoxy Floor Coatings

- Characteristics: Epoxy coatings are known for their strong adhesion, high chemical resistance, and durability. They provide a hard, glossy finish that is ideal for high-traffic areas.

- Applications: Warehouses, factories, commercial kitchens, laboratories, and garage floors.

- Benefits: Chemical resistance, high wear resistance, and a smooth finish that’s easy to clean.

4,Acrylic Floor Coatings

- Characteristics: Acrylic coatings are generally easier to apply and provide a smooth, glossy finish. They are often used for decorative purposes but can also offer protection in low-traffic industrial environments.

- Applications: Retail stores, commercial spaces, and light industrial areas.

- Benefits: Easy application, cost-effective, and aesthetically pleasing finishes.

5,Cementitious Urethane Coatings

- Characteristics: Cementitious urethane is a highly durable flooring system designed for environments with extreme thermal shock, heavy traffic, and chemical exposure.

- Applications: Food processing plants, breweries, and pharmaceutical labs.

- Benefits: Resistant to high temperatures, thermal shock, and chemical spills.

Why choose polyurea coatings?

Key Requirements for Industrial Floor Coatings and Why Polyurea is the Best Option:

1,Durability and Wear Resistance

Polyurea coatings are extremely durable and resistant to abrasion, outperforming traditional coatings like epoxy in high-traffic and heavy-load environments. Unlike epoxy, which can wear down over time, polyurea maintains its integrity longer, reducing maintenance costs.

2,Chemical and Impact Resistance

Polyurea provides superior resistance to chemicals, oils, and solvents compared to other coatings. It also resists impact better, ensuring longer-lasting protection against drops or heavy machinery without cracking, unlike epoxy or polyurethane coatings that may degrade quicker under similar conditions.

3,Seamless and Waterproof

Polyurea offers a seamless finish, preventing the buildup of dirt, bacteria, or contaminants. This seamless, waterproof nature protects against liquid spills more effectively than epoxy, which can crack and allow water or chemicals to seep through joints or seams over time.

4,Temperature and UV Resistance

Polyurea performs well in extreme temperatures, whether hot or cold, and is highly resistant to UV degradation. This makes it more reliable for both indoor and outdoor use compared to other coatings like epoxy, which can yellow or degrade under UV exposure.

5, Longer Lifespan and Better Performance

Unlike fast-reacting polyurea variants, the third-generation polyurea coatings we offer have a slower curing time, which allows for a more stable chemical structure and longer lifespan. This results in better performance and a longer service life compared to standard polyurea or epoxy coatings, offering a more cost-effective solution in the long term.

Polyurea coating construction scheme

Hot-sale Industrial Flooring

Base Coat + Self-Leveling T06N-SL2-UV

- High Flowability:

Self-leveling material spreads evenly, filling uneven floor areas to create a smooth surface - Superior Sealing

Its excellent sealing properties have already resolved capillary issues, eliminating the need for a topcoat. High Strength

Self-leveling polyurea forms a thick, durable film in one step. Once cured, it offers high strength, elasticity, and wear resistance.UV Resistance

Withstands intense sunlight and aging due to excellent UV resistance.

- Recommended Usage:

Primer: 0.15-0.3 kg/㎡

Self-Leveling: 1-2 kg/㎡

Option 2: Primer P02V + Intermediate Coat M02N + Top Coat T06N-GL-UV

- Primer Layer

Seals the substrate surface, enhances adhesion, and provides a solid foundation for subsequent coatings. - Polyurea Intermediate Coat

Increases overall thickness and mechanical strength, smoothens surface irregularities, and offers a seamless transition layer. - Polyurea Top Coat

Serves as the final decorative and protective layer, delivering the desired aesthetic finish and surface properties. - lmportant Note:

After completing one process step, the next step should be covered within 24 hours.If conditions are not sufficient, the substrate must be sanded before the next stepand covered as soon as possible. - Recommended Usage

Primer: 0.15-0.3 kg/㎡

Intermediate Coat: 0.2-2 kg/㎡

Top Coat: 0.15-0.3 kg/㎡

Thin coating process

Option3: Primer P02V + Top Coat T06N-GL-UV

- Base floor requirements

The concrete floor (or other material floor, such as ceramic tile, stone, metal) must be highly flat, with a dense surface and no floating dust. - Polyurea Primer:

Seals and closes the substrate surface, enhancing adhesion for subsequent coatings. - Polyurea Thin Coat:

Serves as the final decorative and protective layer, providing an aesthetically pleasing finish and enhanced performance. - Recommended Material Usage:

Primer: 0.15-0.3 kg/㎡

Top Coat: 0.15-0.3 kg/㎡ - Subfloor flexibility

Thin coating process construction subfloor can be flat concrete, tile, LVT floor, stone plastic floor, epoxy coating floor, polyurethane floor, etc.

Hand-applied Polyurea Coatings

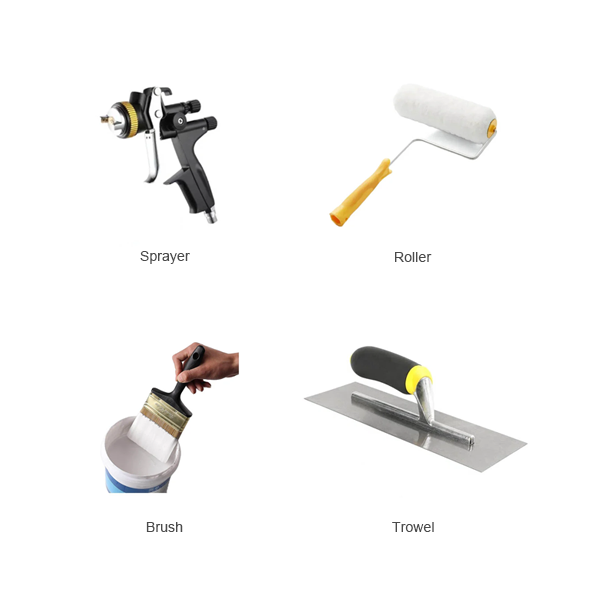

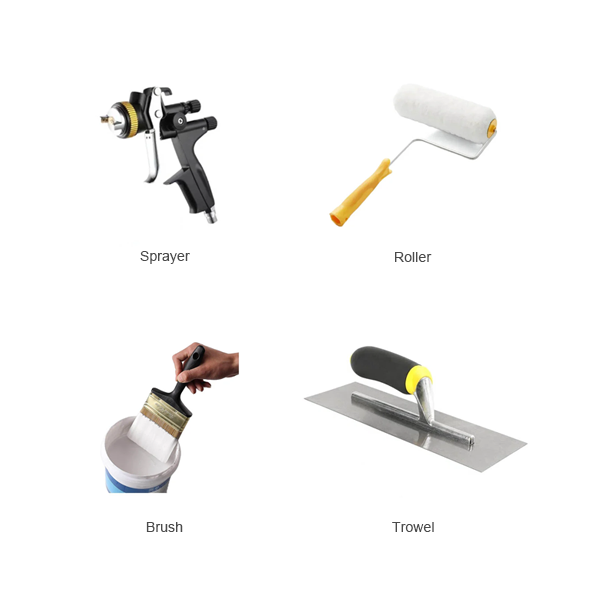

Flexible and diverse construction methods

MPU polyurea polyurethane adopts latent curing technology to appropriately reduce the initial reaction activity of the material, prolong the material operation time, and does not affect the final curing speed and material performance of the material.

MPU polyurea coating can be applied manually by brushing or scraping with a roller brush, a brush, or a trowel, or it can be efficiently sprayed with spray equipment. The construction methods are flexible and diverse.

Application Scenarios

MPU offers high-performance seamless floors and wall systems for a wide range of industries including medical, healthcare, manufacturing, automotive, food and beverage processing, education, hospitality and entertainment, food service, and much more.

Heavy-duty workshop polyurea coating floor

Electronics factory anti-static polyurea floor

Polyurea flooring for circuit board factory

dust-free workshop

Pharmaceutical production workshop polyurea coating floor

Food factory-slaughterhouse

Gas station polyurea coating floor

Outdoor Polyurea Flooring

New energy battery workshop polyurea coating floor

Garment factory polyurea coating floor

Color Service

The MPU Coating floor color card is derived from the German RAL color card, a highly respected standard among color professionals in the international industrial, architectural, and design sectors. The RAL color standard is extensively used in various color matching designs and color calibration processes.

Please note that due to variables such as lighting conditions and display differences, the colors on the electronic card may appear different from the actual paint colors. Therefore, this color card is intended for reference purposes only and should not be used as a standard sample.

Colors can be customized

Colored Quartz can be used with all MPU COATINGS Systems

Decorative flakes can be used with all MPU COATINGS systems

Looking for a Material Safety Data Sheet? (MSDS / SDS) Click the link to complete a request form.

Polyurea is an elastomer derived from step-growth polymerization, which involves combining a synthetic resin and an isocyanate reactive material. It is renowned for its rapid curing time, durability, and resistance to various environmental factors.

Polyurea is used in a wide range of applications including waterproofing, coatings for pipelines, secondary containment, tank linings, flooring, and protective coatings for concrete and steel structures.

Polyurea offers superior benefits such as faster curing times, greater flexibility, excellent abrasion resistance, and strong chemical resistance compared to traditional materials like epoxy and polyurethane.

Polyurea coatings provide outstanding durability, resistance to chemicals and abrasions, waterproofing capabilities, quick application and curing times, and the ability to adhere to a variety of substrates.

Yes, polyurea can be applied in a wide range of temperatures, from sub-zero to high heat environments, making it versatile for various climatic conditions.

Polyurea has an exceptionally fast curing time, typically ranging from seconds to minutes, allowing for quick project turnaround and minimal downtime.

Polyurea is environmentally friendly as it contains no volatile organic compounds (VOCs), solvents, or other hazardous substances, making it safe for use in sensitive environments.

Polyurea can be applied to numerous surfaces including concrete, steel, wood, and other metals, as well as various types of plastics and foam.

The longevity of a polyurea coating depends on the specific application and environmental conditions but typically, polyurea coatings can last for many years, providing long-term protection and performance.

Polyurea coatings require minimal maintenance. Regular cleaning and periodic inspections for any signs of wear or damage will help ensure the longevity and performance of the coating.