Confused by running track options? Choosing wrong means costly mistakes and performance issues. This guide breaks down the main types to help you select wisely for your next project.

Running tracks mainly use synthetic materials like polyurethane (PU) and EPDM rubber granules. Common types include permeable (breathable), composite, mixed, full PU, and EPDM surfaces. Each offers different performance levels, durability characteristics, and installation costs to consider.

Selecting the best surface depends on many factors like budget, intended usage, climate conditions, and desired performance level. As CTO at MPU Coating, I’ve seen how critical this choice is. Let’s explore the specific characteristics of each popular type to help you make an informed decision for your sports facility or project.

What Makes a Permeable Running Track a Popular Choice?

Worried about rain stopping play or training schedules? Waterlogged tracks cause delays and can even lead to long-term damage. Permeable tracks offer excellent drainage, keeping your facility usable much sooner after wet weather.

Permeable tracks, often called breathable tracks, allow water to pass directly through the surface. Their porous structure typically uses EPDM granules bonded with a polyurethane adhesive. This prevents puddles and makes them usable soon after rain, often at a cost-effective price point.

Permeable tracks are a very common choice, especially for school facilities and general training grounds. Their construction is relatively straightforward. The base layer consists of larger EPDM granules (often 2-4mm) mixed with a single-component PU binder. This mixture is paved onto the prepared base (concrete or asphalt). After curing, a top layer is applied. This top layer usually involves spraying a mix of finer EPDM granules (1-3mm) with a colored PU topcoat. The key feature is that the entire structure maintains porosity, allowing rainwater to drain vertically through the track into the sub-base. This design significantly reduces downtime due to weather. While generally durable and offering good basic performance, they might not offer the same energy return or spike resistance as non-permeable systems.

Here’s a quick look at the pros and cons:

| Feature | Description |

|---|---|

| Structure | Porous EPDM/PU Binder Base + PU/EPDM Spray Top |

| Key Benefit | Excellent Drainage (Permeable)1, Cost-Effective2 |

| Performance | Good for General Use, Training |

| Durability | Moderate, Good Lifespan with Maintenance3 |

| Ideal Use | Schools, Training Facilities, Community Tracks |

How Does a Composite Running Track Balance Cost and Performance?

Want better performance and durability than a basic permeable track, but find that full PU systems stretch the budget? High-end tracks can be expensive investments. Composite tracks are designed to offer a middle ground, enhancing performance without reaching the top price tier.

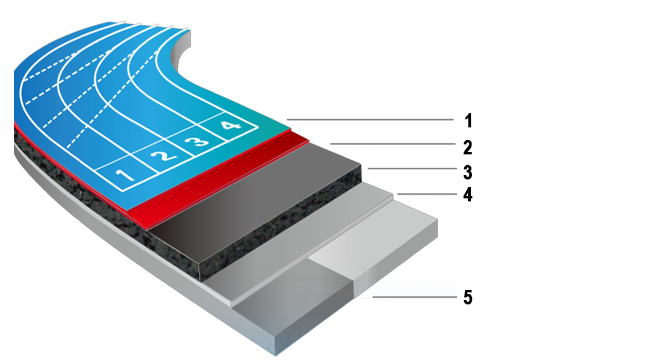

Composite running tracks combine a permeable EPDM/PU binder base layer like the one in permeable tracks, but add a sealed, non-permeable PU layer on top before applying the final spray coat. This offers improved durability and resilience compared to fully permeable tracks, representing a moderate cost option.

The composite system aims to provide a step up in performance and wear resistance4 from the fully permeable type. It starts with the same kind of porous base layer made from EPDM granules and PU binder. However, before the final wear layer is applied, a layer of PU material (often referred to as a sealing layer or structural spray) is applied over the porous base. This layer fills the voids in the top part of the base, creating a non-permeable surface. Finally, a textured wear layer, similar to the spray coat used on permeable tracks (PU mixed with fine EPDM granules), is applied. This structure gives better spike resistance5 and overall durability than permeable tracks because the wear layer sits on a more solid, sealed foundation. While it loses the full permeability, surface drainage is managed through the track’s slope. It’s a popular choice for facilities that host regular activities and some level of competition. We at MPU Coating offer robust polyurethane coatings6 suitable for these applications.

| Feature | Description |

|---|---|

| Structure | Porous Base + PU Sealing Layer + PU/EPDM Spray Top |

| Key Benefit | Good Balance of Cost, Performance, & Durability |

| Performance | Enhanced Resilience Compared to Permeable |

| Durability | Good, Better Wear Resistance than Permeable |

| Ideal Use | Schools with Competitions, Regional Venues |

Why is the Mixed Running Track System Favored for Many Competitions?

Need a track that’s tough enough for frequent use, including regular athletic competitions? Basic surfaces might wear down quickly under constant stress from spikes and heavy use. Mixed tracks, sometimes called sandwich systems, provide the durability and performance characteristics needed for competitive environments.

Mixed running tracks feature a resilient base layer made from polyurethane binder mixed with rubber granules (EPDM or recycled SBR), topped with a wear layer of sprayed PU coating embedded with colored EPDM granules. They offer excellent elasticity, shock absorption, and durability suitable for many levels of competition.

The mixed system is a true workhorse in the world of running tracks. Its base layer is different from the permeable type. Here, a two-component PU binder is mixed with rubber granules (often black recycled SBR for cost-effectiveness, or EPDM) and paved to form a solid, resilient cushion layer, typically around 9-10mm thick. This base provides excellent shock absorption and elasticity. After the base cures, a top layer is applied. This consists of a high-quality PU coating sprayed onto the base, into which fine colored EPDM granules (1-3mm) are embedded while the PU is still wet. This creates a textured, durable, and spike-resistant surface. This system offers significantly better performance characteristics (like energy return) and durability compared to permeable or composite tracks. It meets requirements for many competitive events and is a common choice for university tracks and regional stadiums. Its all-weather capability and good balance of performance and cost make it very popular.

| Feature | Description |

|---|---|

| Structure | PU Binder/Granule Base + PU/EPDM Spray Top Layer |

| Key Benefit | High Performance, Excellent Durability |

| Performance | Competition Grade Elasticity & Shock Absorption |

| Durability | Very Good, Handles Frequent Spike Use Well |

| Ideal Use | Competition Venues, Universities, Sports Clubs |

When Should You Invest in a Full Polyurethane (Full PU) Running Track?

Aiming for the absolute highest level of athletic performance and maximum track lifespan for a premier facility? Compromising on the surface can impact athlete performance and require earlier replacement. Full PU track systems represent the premium tier, delivering top quality and durability.

Full PU running tracks consist entirely of paved or poured polyurethane layers, typically without loose rubber granules in the base structure. They offer superior elasticity, energy return, and outstanding durability, making them the preferred choice for elite international competitions. Finishes can be particle-sprayed or smooth self-leveling.

Full PU tracks7 are the pinnacle of running track technology, designed for world-class performance. Unlike mixed systems, the base layers are typically composed entirely of PU material, often applied in multiple layers using paving machines. This creates an exceptionally uniform and resilient foundation. There are generally two main types of finishes for Full PU tracks7:

- Particle Finish: Similar to the mixed track topcoat, a layer of PU is applied, and then EPDM or PU granules are embedded into it for texture and spike resistance.

- Self-Leveling Finish8: A specialized PU topcoat is poured and spread, which levels itself out to create a very smooth, seamless, and highly resilient surface. This is often seen in top international stadiums.

These systems provide the best energy return9 for athletes and have exceptional durability and weather resistance. They represent the highest investment but offer the longest service life and meet the stringent standards of organizations like World Athletics for major championships. At MPU Coating, our expertise extends to these high-performance systems, leveraging advanced polymer chemistry.

| Feature | Description |

|---|---|

| Structure | Solid PU Base Layers + PU Top (Particle or Self-Leveling) |

| Key Benefit | Maximum Performance, Longevity, Elite Standard |

| Performance | Superior Elasticity, Energy Return, Uniformity |

| Durability | Exceptional, Designed for Highest Level Use |

| Ideal Use | Professional Stadiums, International Competitions |

What About EPDM Surfaces for General Activity Areas?

Planning a playground, kindergarten outdoor area, or a multi-use recreational space rather than a formal running track? Hard surfaces like concrete or asphalt can lead to injuries during play. EPDM surfaces offer safety cushioning, vibrant colors, and durability suitable for these general activities.

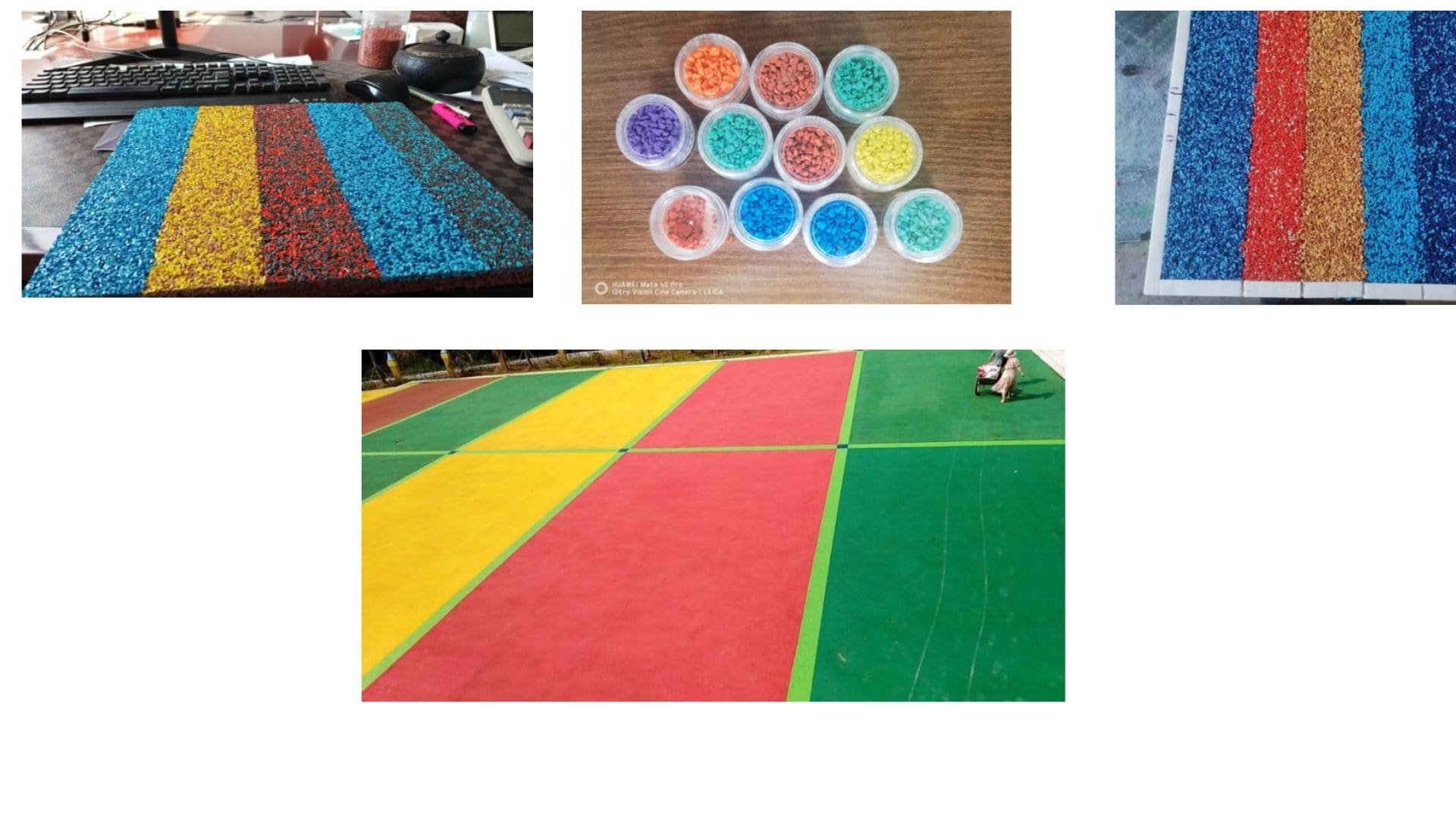

EPDM surfaces use colored EPDM rubber granules thoroughly mixed with a PU binder, then paved onto a prepared base. They provide excellent impact absorption (safety), good slip resistance, and allow for creative and vibrant designs, perfect for playgrounds, walkways, and multi-sport recreational areas.

While not typically used for competitive running tracks due to different performance characteristics, EPDM surfaces are ideal for a wide range of other applications where safety and aesthetics are key. The system usually involves mixing high-quality, colored EPDM granules (available in many hues) with a clear PU binder. This mixture is then troweled or paved onto the base, often in two layers: a base cushion layer made of coarser black recycled rubber (SBR) granules bound with PU for cost-effectiveness and shock absorption, followed by a top wear layer of the colored EPDM granule mix. The thickness can be adjusted based on safety requirements (e.g., critical fall height for playground equipment). Key benefits include excellent weather resistance, UV stability (important for color retention – binder quality matters here!), slip resistance, and providing a cushioned, safe surface. The ability to create intricate patterns and designs with different colors makes EPDM a favorite for visually appealing recreational spaces.

| Feature | Description |

|---|---|

| Structure | EPDM Granules (Colored/Black) + PU Binder |

| Key Benefit | Safety Cushioning, Color Variety, Versatility |

| Performance | Impact Absorbing, Slip Resistant |

| Durability | Good for Recreational Use, Easy Maintenance |

| Ideal Use | Playgrounds, Kindergartens, Multi-Use Areas |

Conclusion

Choosing the right running track surface involves balancing needs like performance, budget, climate, and maintenance. Understanding these different types helps you specify the best solution for your project and partner effectively with experienced suppliers like us.

External Links

-

Understanding the benefits of excellent drainage can help you appreciate the design and functionality of permeable tracks. ↩

-

Exploring the cost-effectiveness of permeable tracks can provide insights into their long-term value for facilities. ↩

-

Learning about maintenance practices can ensure the longevity and performance of your permeable track investment. ↩

-

Learn about the importance of wear resistance in sports tracks and how it affects longevity and safety. ↩

-

Discover why spike resistance is crucial for sports tracks, especially for competitive events, ensuring safety and performance. ↩

-

Explore this link to understand how polyurethane coatings enhance performance and durability in sports facilities. ↩

-

Explore the advantages of Full PU tracks for athletes, including performance and durability, to understand why they are the top choice in running technology. ↩ ↩

-

Learn about the Self-Leveling Finish and its benefits for creating smooth, resilient surfaces in professional stadiums. ↩

-

Discover the concept of energy return in running tracks and how it impacts athlete performance and comfort during competitions. ↩