Equipment Protection Polyurea

Definition of Polyurea

Polyurea

Polyurea is a type of synthetic polymer produced by the reaction of a diamine and a diisocyanate, characterized by its urea linkages, rapid curing time, and high durability. It is widely used for its excellent waterproofing and protective properties.

History of Polyurea

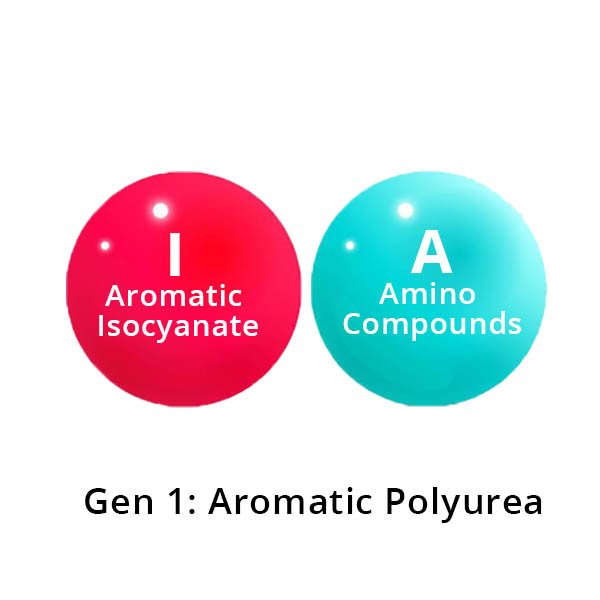

Gen 1: Aromatic Polyurea

The 1st generation of polyurea coatings emerged in the early 1990s. These coatings were characterized by their extremely fast reaction times, which posed challenges in terms of application and adhesion. Early polyurea formulations often suffered from poor adhesion and limited raw material availability, leading to a higher incidence of coating failures

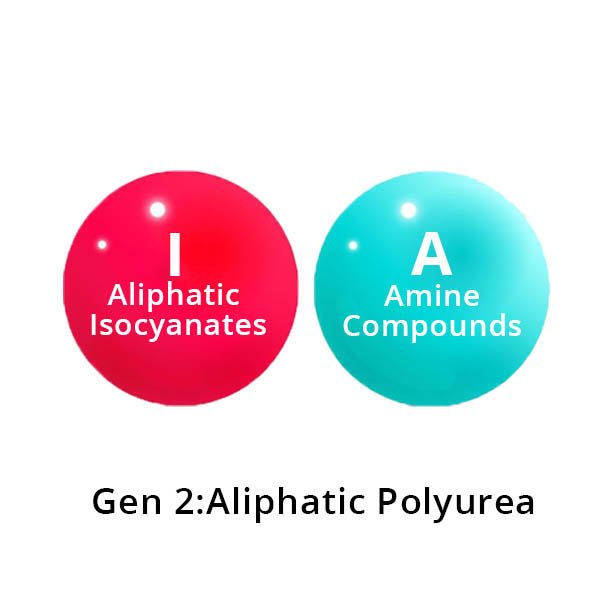

Gen 2 - Aliphatic Polyurea

By the early 2000s, the 2nd generation of polyurea coatings had been developed. These coatings featured significant improvements in hardness, chemical resistance, and reduced volatile organic compounds (VOCs). The advancements in raw materials, such as the introduction of secondary diamines, allowed for better control over the gel times, enhancing the adhesion and overall performance of the coatings

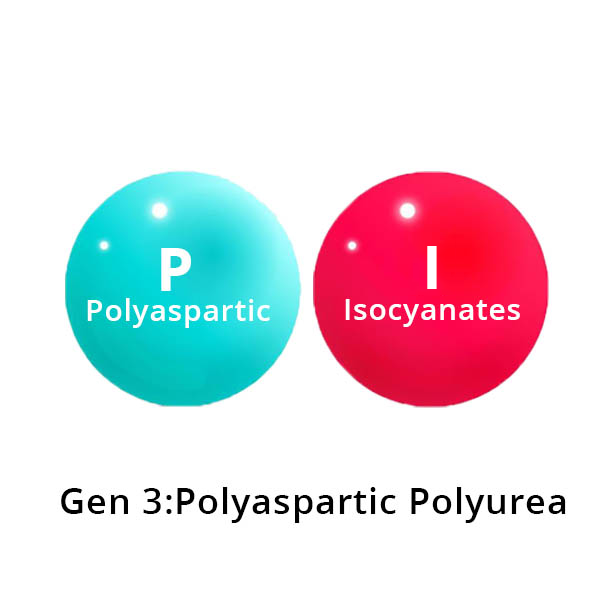

Gen 3 - Polyaspartic Polyurea

Polyaspartic polyurea is the 3rd generation of polyurea, it’s an aliphatic polyurea coating derived from the reaction of an aliphatic polyisocyanate with an aliphatic diamine (specifically a polyaspartic ester). It is essentially a slowed-down version of polyurea, allowing for easier application while retaining many beneficial properties.

Hand-applied Polyurea Coatings

Sprayer

Brush

Roller

Trowel

Latent Curing Technology

High-performance polyurea and polyurethane both have the problem of too fast reaction speed and short service life, which brings a lot of troubles to practical applications. MPU polyurea polyurethane adopts latent curing technology to appropriately reduce the initial reaction activity of the material, prolong the material operation time, and does not affect the final curing speed and material performance of the material. The figure below shows the comparison of the curing rate viscosity time curve and hardness time relationship of conventional and latent curing technology.

Features of Polyurea

Polyaspartic polyurea coatings are known for their advanced and desirable properties, making them suitable for a wide range of industrial and commercial applications. Here are the key features:

1. Rapid Curing

- Fast Drying: Can cure in a few hours, reducing project time and downtime.

- Cold Temperature Application: Effective curing in both hot and cold conditions.

2. Durability

- Impact Resistance: Withstands heavy impacts without damage.

- Flexibility: Adapts to substrate movements without cracking.

3. Chemical Resistance

- Resistance to Chemicals: Stands up to oils, solvents, and cleaning agents.

- Corrosion Prevention: Protects metal surfaces from rust and corrosion.

4. UV Stability

- UV Resistant: Does not yellow or degrade when exposed to sunlight.

- Color Retention: Maintains original color and gloss over time.

5. Abrasion Resistance

- Wear-Resistant: Ideal for high-traffic areas due to superior abrasion resistance.

6. Adhesion

- Strong Bonding: Adheres well to various substrates including concrete, metal, and wood.

- Self-Priming: Often does not require a separate primer, simplifying the application process.

7. Aesthetic Versatility

- Customizable Appearance: Available in multiple colors and finishes (clear, matte, glossy).

- Decorative Options: Can incorporate flakes and pigments for decorative purposes.

8. Low VOC Content

- Environmentally Friendly: Low in volatile organic compounds (VOCs), making it safer for indoor use and more environmentally friendly.

9. Ease of Maintenance

- Simple Cleaning: Surfaces can be cleaned easily with mild detergents.

- Stain Resistance: Resists stains from common contaminants like grease and oil.

10. Flexible Application

- Versatile Application Methods: Can be applied using airless spray or by hand brushing.

Polyurea Coatings

Self-levelling Polyurea

Ultra Abrasion-Resistant Polyurea

Self-levelling Colored Sand Polyurea

Midcoat Polyurea

Flat Topcoat Polyurea

Primer Epoxy

Applications of Polyurea

Swimming Pools

Garage

Industrial Flooring

Facade

Commercial Flooring

School

Hospital

Residential

Equipment Protection

Color Service

MPU Coating Floor Color Card

The MPU Coating floor color card is derived from the German RAL color card, a highly respected standard among color professionals in the international industrial, architectural, and design sectors. The RAL color standard is extensively used in various color matching designs and color calibration processes.

Please note that due to variables such as lighting conditions and display differences, the colors on the electronic card may appear different from the actual paint colors. Therefore, this color card is intended for reference purposes only and should not be used as a standard sample.

Colors can be customized

Colors can be customized

Looking for a Material Safety Data Sheet? (MSDS / SDS) Click the link to complete a request form.

Polyurea is an elastomer derived from step-growth polymerization, which involves combining a synthetic resin and an isocyanate reactive material. It is renowned for its rapid curing time, durability, and resistance to various environmental factors.

Polyurea is used in a wide range of applications including waterproofing, coatings for pipelines, secondary containment, tank linings, flooring, and protective coatings for concrete and steel structures.

Polyurea offers superior benefits such as faster curing times, greater flexibility, excellent abrasion resistance, and strong chemical resistance compared to traditional materials like epoxy and polyurethane.

Polyurea coatings provide outstanding durability, resistance to chemicals and abrasions, waterproofing capabilities, quick application and curing times, and the ability to adhere to a variety of substrates.

Yes, polyurea can be applied in a wide range of temperatures, from sub-zero to high heat environments, making it versatile for various climatic conditions.

Polyurea has an exceptionally fast curing time, typically ranging from seconds to minutes, allowing for quick project turnaround and minimal downtime.

Polyurea is environmentally friendly as it contains no volatile organic compounds (VOCs), solvents, or other hazardous substances, making it safe for use in sensitive environments.

Polyurea can be applied to numerous surfaces including concrete, steel, wood, and other metals, as well as various types of plastics and foam.

The longevity of a polyurea coating depends on the specific application and environmental conditions but typically, polyurea coatings can last for many years, providing long-term protection and performance.

Polyurea coatings require minimal maintenance. Regular cleaning and periodic inspections for any signs of wear or damage will help ensure the longevity and performance of the coating.