Facade Polyurea

Unlike traditional materials, polyurea withstands extreme temperatures, UV rays, and rain erosion, ensuring long-term durability and stability.

Your trusted supplier of Facade polyurea coatings

At MPU COATINGS, we offer functional, cost-effective solutions for commercial clients, catering to unique design and construction needs. Our third-generation polyurea industrial coatings are engineered to surpass traditional epoxy, providing superior durability, abrasion resistance, and UV protection.

Our self-leveling polyurea eliminates the need for a topcoat, enhancing application efficiency. Specializing in polyaspartic acid, amine compounds, and latent curing technology, we deliver high-performance solutions with color-fast coatings for facades, ensuring long-lasting architectural finishes.

Customized for OEM/ODM, our coatings meet specific brand, color, packaging, and application requirements. Trust our chemical expertise to elevate your projects with unmatched performance and longevity.

Facade Polyurea Overview

Key Features

- Exceptional Durability: Offers a service life of up to 25 years, capable of withstanding extreme temperature fluctuations without splitting or peeling.

- Waterproof and UV Resistant: Provides long-term resistance to rain erosion, prevents water penetration, and maintains color integrity without yellowing under UV exposure.

- Easy Application: Can be applied seamlessly with an airless spray or brush, ensuring a simple and flexible construction process.

- Effortless Maintenance: The exterior polyurea coating is designed for easy cleaning, reducing maintenance time and effort.

- Versatile Color Options: Available in custom colors or with colored quartz, offering aesthetic flexibility to match any design needs.

Polyurea coating construction scheme

Spraying solution

Primer EW02 + Top Coat M06T-UV

- Polyurea Primer:

Use a high-pressure spray machine to apply a thin, even coat, sealing and preparing the substrate for enhanced adhesion. Ensure complete coverage and proper curing. - Polyurea Thin Coat:

Use a high-pressure spray machine to apply multiple thin layers , achieving a smooth, protective, and decorative finish. Follow curing guidelines and inspect for a flawless result. - Recommended Material Usage:

Primer: 0.15-0.5 kg/㎡

Top Coat: 0.1-0.25 kg/㎡

Thin coating process

Option3: Primer EW02 + Top Coat M06T-UV

- Base floor requirements

The concrete floor (or other material floor, such as ceramic tile, stone, metal) must be highly flat, with a dense surface and no floating dust. - Polyurea Primer:

Seals and closes the substrate surface, enhancing adhesion for subsequent coatings. - Polyurea Thin Coat:

Serves as the final decorative and protective layer, providing an aesthetically pleasing finish and enhanced performance. - Recommended Material Usage:

Primer: 0.15-0.5 kg/㎡

Top Coat: 0.1-0.25 kg/㎡ - Subfloor flexibility

Thin coating process construction subfloor can be flat concrete, tile, LVT floor, stone plastic floor, epoxy coating floor, polyurethane floor, etc.

Hand-applied Polyurea Coatings

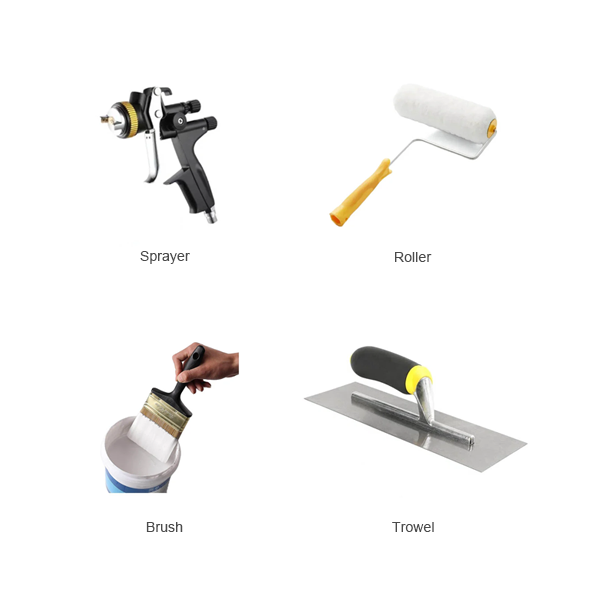

Flexible and diverse construction methods

MPU polyurea polyurethane adopts latent curing technology to appropriately reduce the initial reaction activity of the material, prolong the material operation time, and does not affect the final curing speed and material performance of the material.

MPU polyurea coating can be applied manually by brushing or scraping with a roller brush, a brush, or a trowel, or it can be efficiently sprayed with spray equipment. The construction methods are flexible and diverse.

Features of Polyurea

Polyaspartic polyurea coatings are perfect for facade, offering low odor, VOC-exempt performance, and non-yellowing properties. They ensure unmatched durability and chemical resistance, providing safe, long-lasting surfaces with a quick, one-day installation.

1. Exceptional Durability and Waterproofing:

- Polyurea coatings offer superior durability and waterproofing, protecting facades from water infiltration, mechanical stress, and environmental damage.

2.Rapid Curing and Flexibility

- These coatings cure quickly, minimizing downtime, and exhibit excellent flexibility, allowing them to bridge cracks and adapt to structural movements without peeling or cracking.

3. Anti-UV

- Polyurea is highly resistant to UV radiation and, ensuring long-term color stability and protection against pollutants and corrosive substances.

4. Versatility and Strong Adhesion

- Polyurea can be applied to various substrates, including concrete, metal, and wood, with strong adhesion, making it suitable for diverse architectural designs and materials.

5. Environmental Friendliness and Aesthetic Customization

- Free of volatile organic compounds (VOCs), polyurea is environmentally friendly and can be pigmented for aesthetic customization, maintaining visual appeal over time.

Application Scenarios

Color Service

The MPU Coating floor color card is derived from the German RAL color card, a highly respected standard among color professionals in the international industrial, architectural, and design sectors. The RAL color standard is extensively used in various color matching designs and color calibration processes.

Please note that due to variables such as lighting conditions and display differences, the colors on the electronic card may appear different from the actual paint colors. Therefore, this color card is intended for reference purposes only and should not be used as a standard sample.

Colors can be customized

Colored Quartz can be used with all MPU COATINGS Systems

Decorative flakes can be used with all MPU COATINGS systems

Looking for a Material Safety Data Sheet? (MSDS / SDS) Click the link to complete a request form.

Polyurea is an elastomer derived from step-growth polymerization, which involves combining a synthetic resin and an isocyanate reactive material. It is renowned for its rapid curing time, durability, and resistance to various environmental factors.

Polyurea is used in a wide range of applications including waterproofing, coatings for pipelines, secondary containment, tank linings, flooring, and protective coatings for concrete and steel structures.

Polyurea offers superior benefits such as faster curing times, greater flexibility, excellent abrasion resistance, and strong chemical resistance compared to traditional materials like epoxy and polyurethane.

Polyurea coatings provide outstanding durability, resistance to chemicals and abrasions, waterproofing capabilities, quick application and curing times, and the ability to adhere to a variety of substrates.

Yes, polyurea can be applied in a wide range of temperatures, from sub-zero to high heat environments, making it versatile for various climatic conditions.

Polyurea has an exceptionally fast curing time, typically ranging from seconds to minutes, allowing for quick project turnaround and minimal downtime.

Polyurea is environmentally friendly as it contains no volatile organic compounds (VOCs), solvents, or other hazardous substances, making it safe for use in sensitive environments.

Polyurea can be applied to numerous surfaces including concrete, steel, wood, and other metals, as well as various types of plastics and foam.

The longevity of a polyurea coating depends on the specific application and environmental conditions but typically, polyurea coatings can last for many years, providing long-term protection and performance.

Polyurea coatings require minimal maintenance. Regular cleaning and periodic inspections for any signs of wear or damage will help ensure the longevity and performance of the coating.