Swimming pool waterproofing solutions

polyurea coatings: Excellent swimming pool waterproofing products

Your trusted supplier of swimming pool polyurea coatings

Advantages of polyurea waterproof coatings

Compared with epoxy, polyurethane, and acrylic, understand why polyurea coatings are the most suitable for swimming pool coatings.

1, Water Resistance

2, Durability

3, Chemical Resistance

4, safe and nontoxic

5, Nstallation

6, UV Resistance

Polyurea coatings construction scheme

Swimming Pool Flooring

Option 1: Self-Leveling T06N-SL1-UV

Base Coat + Self-Leveling

- High Flowability: T06N-SL1-UV self – leveling material is an outstanding product among swimming pool coating products. It spreads evenly, filling uneven floor areas to create a smooth surface, which is especially useful for swimming pool waterproofing. Its superior sealing properties address capillary issues, eliminating the need for a sealing topcoat, providing an excellent swimming pool coating option.

Easy Application: Mix the material in the recommended ratio, pour onto the floor, and let it self-level.

Smooth Finish: Achieves high flatness and smoothness without extra sanding or polishing.

High Strength: Cured material offers high strength, elasticity, and wear resistance.

Quick Curing: Cures rapidly, walkable within 24 hours, ready for construction in 72 hours.

UV Resistance: Withstands intense sunlight and aging due to excellent UV resistance.

- Recommended Usage:

- Primer: 0.15-0.3 kg/㎡

- Self-Leveling: 1-2 kg/㎡

Option 2: Primer P02V + Intermediate Coat M02N + Top Coat T06N-GL-UV

- Primer Layer

Seals the substrate surface, enhances adhesion, and provides a solid foundation for subsequent coatings. - Polyurea Intermediate Coat

Increases overall thickness and mechanical strength, smoothens surface irregularities, and offers a seamless transition layer. - Polyurea Top Coat

Serves as the final decorative and protective layer, delivering the desired aesthetic finish and surface properties. - lmportant Note:

After completing one process step, the next step should be covered within 24 hours.If conditions are not sufficient, the substrate must be sanded before the next stepand covered as soon as possible. - Recommended Usage

Primer: 0.15-0.5 kg/㎡

Intermediate Coat: 0.2-2 kg/㎡

Top Coat: 0.15-0.3 kg/㎡

Pool Wall

Primer P02V + Top Coat T06N-GL-UV

Polyurea Primer:

- Polyurea Primer:

Function: It plays a crucial role in swimming pool waterproofing. It seals and closes the substrate surface, significantly enhancing adhesion for subsequent coatings, ensuring the stability of the swimming pool structure. - Polyurea Thin Coat:

Function: As the final decorative and protective layer among swimming pool coating options, it provides an aesthetically pleasing finish and enhanced performance, protecting the pool walls effectively. - Recommended Material Usage:

Primer: 0.15-0.3 kg/㎡

Top Coat: 0.15-0.3 kg/㎡ - Important Note: After completing one process step, the next step should be covered within 24 hours. If conditions are not sufficient, the substrate must be sanded before the next step and covered as soon as possible. For pool surfaces, it is recommended to use a self-leveling method, which reduces the number of steps, significantly lowering the operational difficulty and risk.

Hand-applied Polyurea Coatings

Flexible and diverse construction methods

MPU polyurea polyurethane adopts latent curing technology to appropriately reduce the initial reaction activity of the material, prolong the material operation time, and does not affect the final curing speed and material performance of the material.

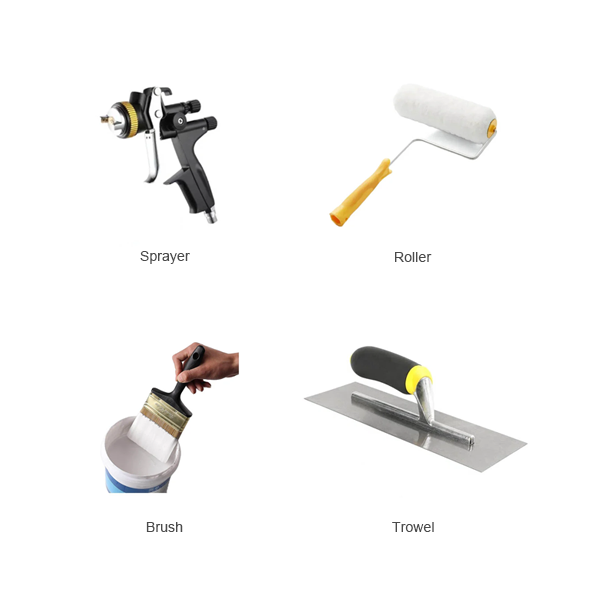

MPU polyurea coating can be applied manually by brushing or scraping with a roller brush, a brush, or a trowel, or it can be efficiently sprayed with spray equipment. The construction methods are flexible and diverse.

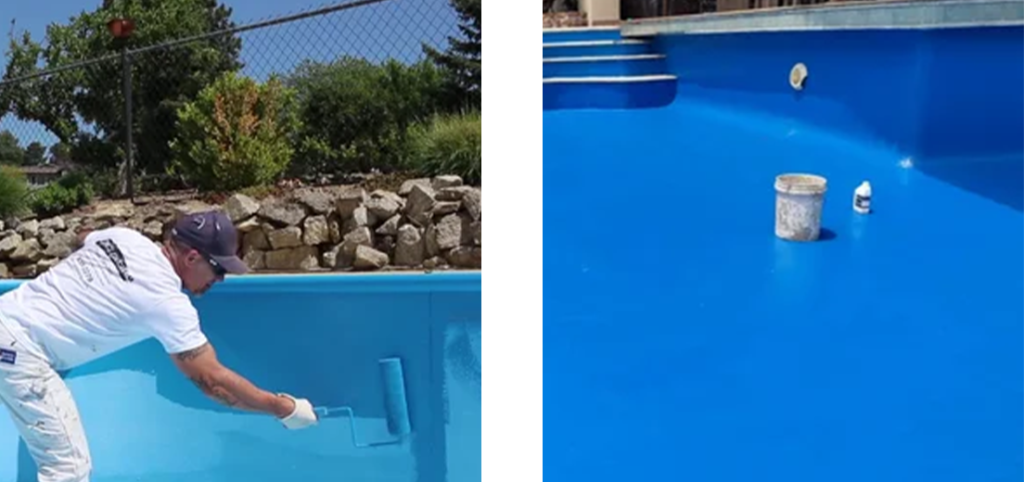

Indoor Swimming Pool

Outdoor Swimming Pool

Color Service

The MPU Coating floor color card is derived from the German RAL color card, a highly respected standard among color professionals in the international industrial, architectural, and design sectors. The RAL color standard is extensively used in various color matching designs and color calibration processes.

Please note that due to variables such as lighting conditions and display differences, the colors on the electronic card may appear different from the actual paint colors. Therefore, this color card is intended for reference purposes only and should not be used as a standard sample.

Colors can be customized

Colored Quartz can be used with all MPU COATINGS Systems

Decorative flakes can be used with all MPU COATINGS systems

Looking for a Material Safety Data Sheet? (MSDS / SDS) Click the link to complete a request form.

Polyurea is an elastomer derived from step-growth polymerization, which involves combining a synthetic resin and an isocyanate reactive material. It is known for its good water resistance, durability, and resistance to various environmental factors.

Polyurea is used in a wide range of applications including waterproofing, coatings for pipelines, secondary containment, tank linings, flooring, and protective coatings for concrete and steel structures.

Polyurea offers superior benefits such as faster curing times, greater flexibility, excellent abrasion resistance, and strong chemical resistance compared to traditional materials like epoxy and polyurethane.

Polyurea coatings provide outstanding durability, resistance to chemicals and abrasions, waterproofing capabilities, quick application and curing times, and the ability to adhere to a variety of substrates.

Yes, polyurea can be applied in a wide range of temperatures, from sub-zero to high heat environments, making it versatile for various climatic conditions.

Polyurea has an exceptionally fast curing time, typically ranging from seconds to minutes, allowing for quick project turnaround and minimal downtime.

Polyurea is environmentally friendly as it contains no volatile organic compounds (VOCs), solvents, or other hazardous substances, making it safe for use in sensitive environments.

Polyurea can be applied to numerous surfaces including concrete, steel, wood, and other metals, as well as various types of plastics and foam.

The longevity of a polyurea coating depends on the specific application and environmental conditions but typically, polyurea coatings can last for many years, providing long-term protection and performance.

Polyurea coatings require minimal maintenance. Regular cleaning and periodic inspections for any signs of wear or damage will help ensure the longevity and performance of the coating.