Your trusted Spray Foam Insulation material supplier

MPU is dedicated to the development and production of high-quality, environmentally friendly materials for applications in construction, automotive, aerospace, and other industries. Our Spray Foam Insulation undergo rigorous testing to ensure they do not chalk or crack after 1,500 hours of exposure to sunlight, thereby maintaining superior performance over time. Additionally, our coatings are engineered to prevent color and oil bleeding, and they have successfully passed mold testing, confirming their resistance to mold, rot, and odor emissions.

Designed for OEM and ODM applications, our custom coatings can be tailored to meet your specific requirements, including brand specifications, color choices, packaging, and application needs. Rely on our chemical expertise to deliver solutions that consistently exceed your expectations. Contact MPU COATINGS today to enhance your sports program.

About Spray Foam Insulation

Polyurethane Spray Foam Insulation (Also called “steel resin”) is a highly efficient and durable thermal insulation material, commonly used for insulation and sealing of walls, roofs, floors and other parts of buildings, industries and commercial places. Polyurethane foam is a material that is mixed with two components (component A and component B) and sprayed through a spraying device. It has excellent thermal insulation and sealing effects.

Features of Spray Foam Insulation

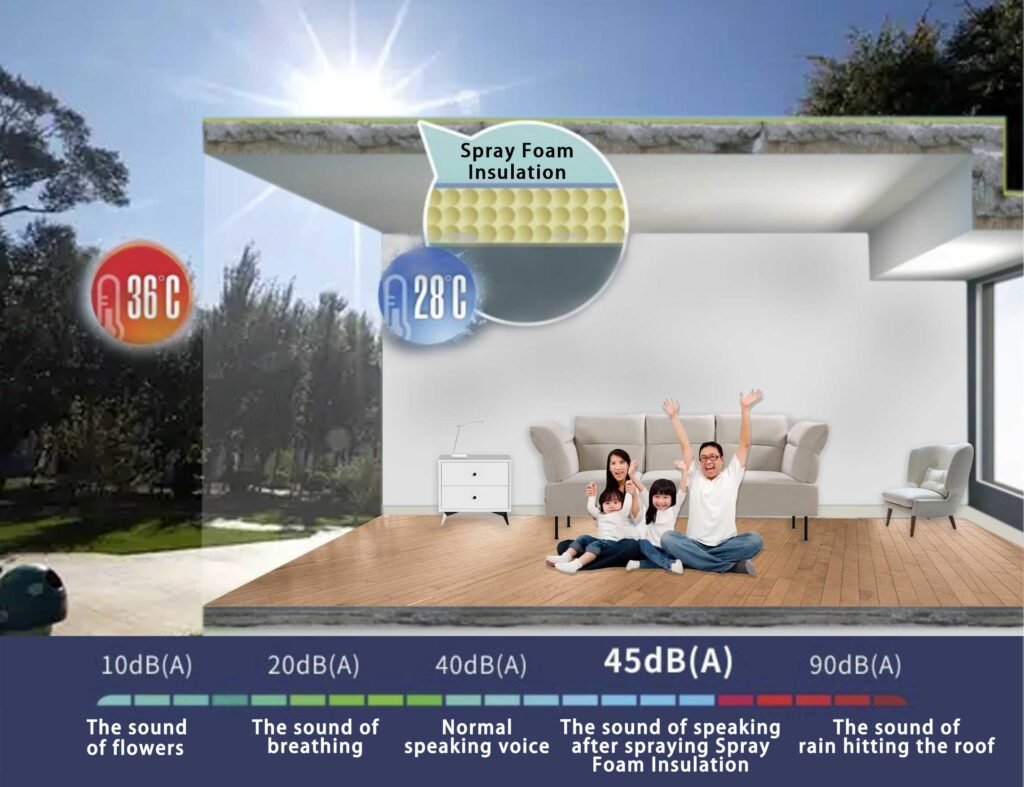

1,Thermal insulation and noise reduction

Spray Foam Insulation uses high-density closed-cell foaming technology, and each bubble is independent of the other. It isolates the temperature transfer and perfectly solves the problem of too high temperature in summer and too low temperature in winter in concrete structures. At the same time, the foam has strong adsorption and obvious noise reduction effect, solving the noise problem caused by the concrete roof being hit by rain and other weather conditions.

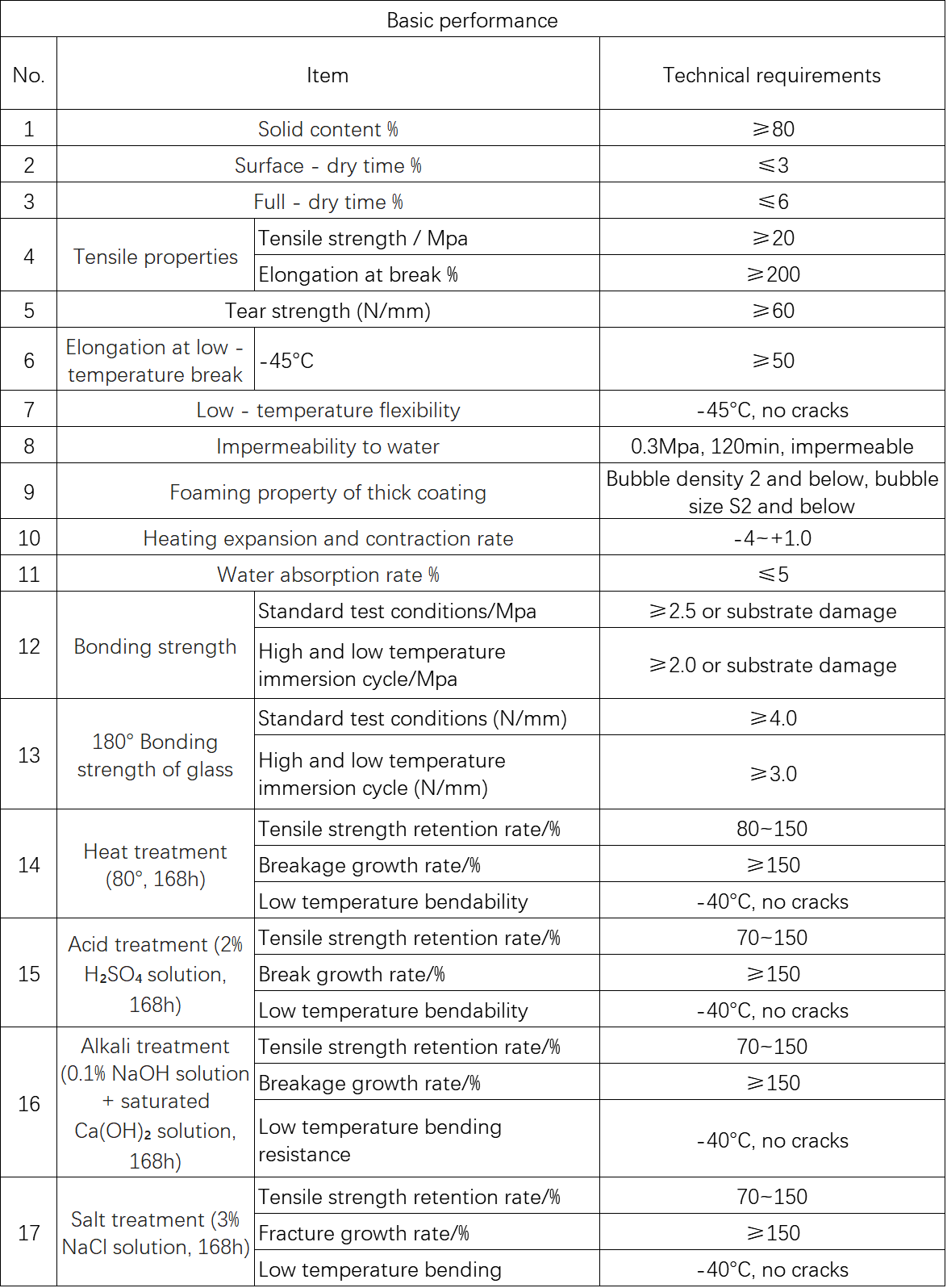

2,Physical properties

Spray foam insulation offers outstanding thermal, waterproofing, soundproofing, compressive strength, and durability properties. With its low thermal conductivity and closed-cell structure, it effectively blocks heat transfer and moisture infiltration while providing excellent compressive strength and structural support. Additionally, spray foam has superior sound absorption qualities, significantly reducing noise transmission, making it ideal for various construction and industrial applications. Its chemical resistance and long lifespan ensure stability in demanding environments, while its eco-friendly formulation enhances energy efficiency, making it an ideal modern insulation material.

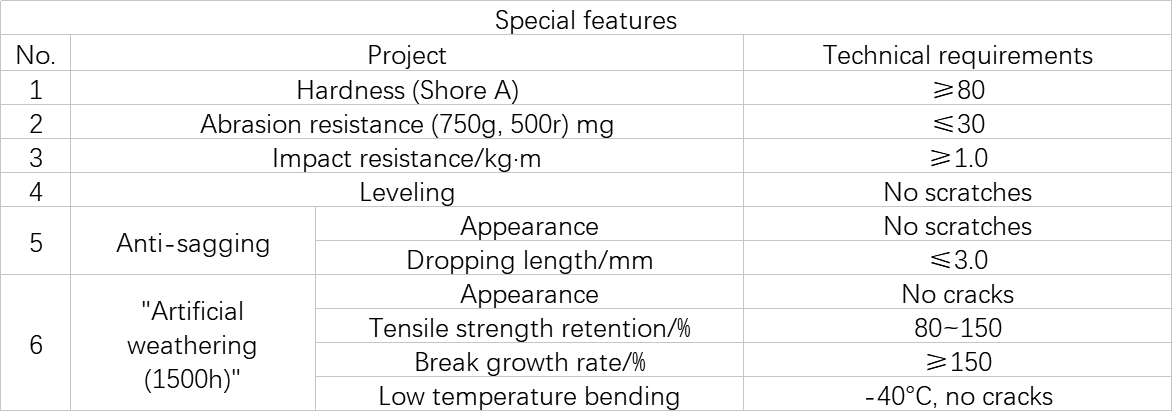

3.,Durable, wear-resistant and aging-resistant

The aliphatic polyurea surface layer can withstand sunlight, temperature changes, wind and rain, alkali resistance, no fading, no discoloration, no cracking, no powdering, and no delamination.

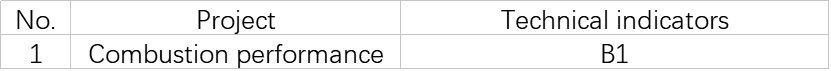

4.,Fire protection reaches B1 level

Fire-resistant and not easy to burn, extinguished away from fire

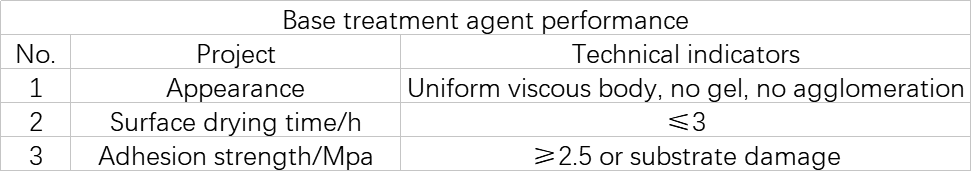

5,Adhesion

The waterproof layer is tightly adhered to the base layer, the topcoat is tightly adhered to the waterproof layer, and the layers are tightly linked to achieve a waterproof decoration effect.

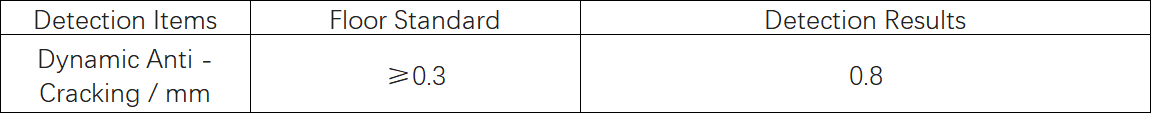

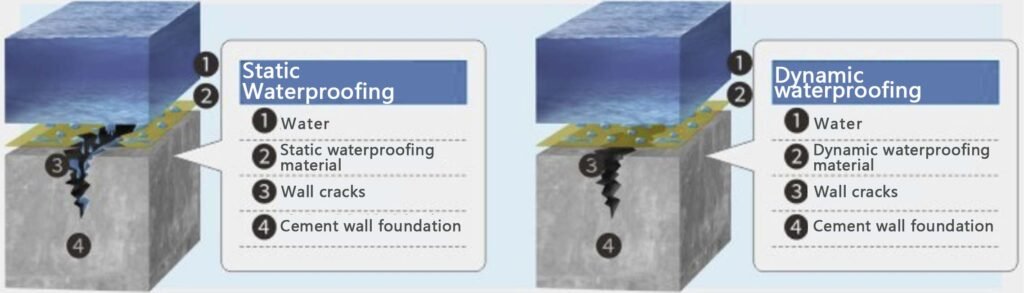

6. Dynamic anti-cracking waterproofing

The whole is seamless, fully covered and integrated. The base layer expands and contracts with heat and cold, and cracks. The waterproof layer expands and contracts with the base layer to maintain a complete waterproof membrane.

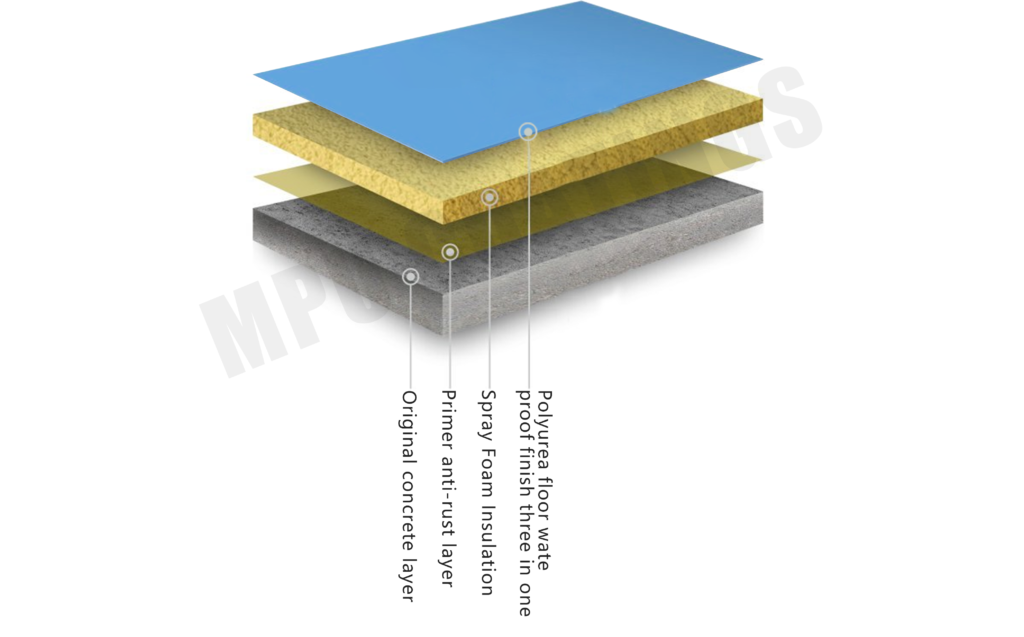

Spray Foam Insulation Construction Steps

1,Cleaning the surface

Treat the concrete surface according to the construction instructions, remove surface dust and meet construction requirements.

2,Roller anti-rust primer

Apply the special anti-rust primer in one or two coats by rolling or scraping on the base surface.

3,Spray Foam Insulation Construction

Debug the sprayer and spray the Spray Foam Insulation paint evenly on the anti-rust primer layer to maintain the uniformity of the Spray Foam Insulation.

4,Polyurea Topcoat Construction

Use a spatula or a brush roller to evenly apply the polyurea topcoat (floor waterproof finish three-in-one) on the Spray Foam Insulation.