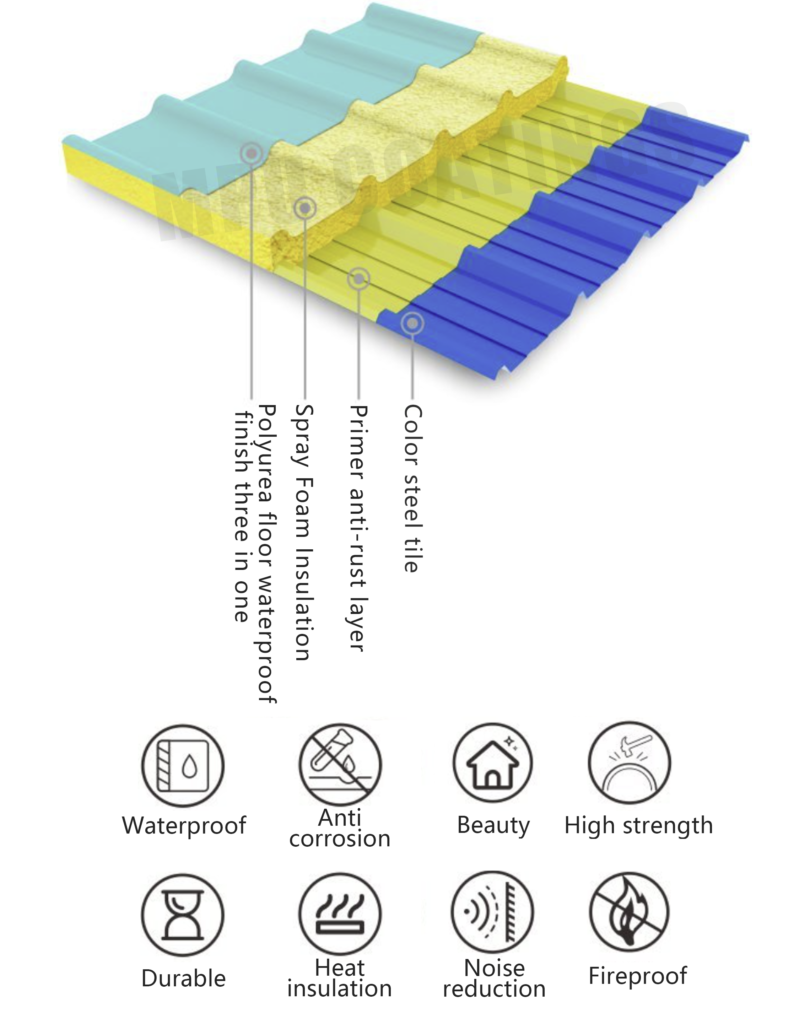

Color Steel Tile Repair System

Enhance Your Colored Steel Buildings with Spray Foam Insulation

Your trusted Spray Foam Insulation material supplier

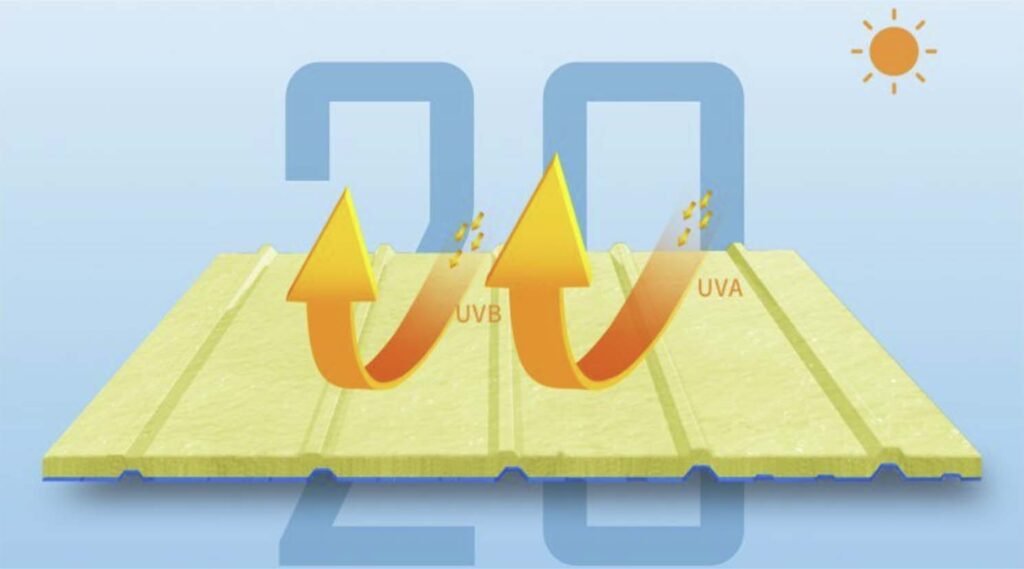

MPU is dedicated to the development and production of high-quality, environmentally friendly materials for applications in construction, automotive, aerospace, and other industries. Our Spray Foam Insulation undergo rigorous testing to ensure they do not chalk or crack after 1,500 hours of exposure to sunlight, thereby maintaining superior performance over time. Additionally, our coatings are engineered to prevent color and oil bleeding, and they have successfully passed mold testing, confirming their resistance to mold, rot, and odor emissions.

Designed for OEM and ODM applications, our custom coatings can be tailored to meet your specific requirements, including brand specifications, color choices, packaging, and application needs. Rely on our chemical expertise to deliver solutions that consistently exceed your expectations. Contact MPU COATINGS today to enhance your sports program.

About Spray Foam Insulation

Polyurethane Spray Foam Insulation (Also called “steel resin”) is a highly efficient and durable thermal insulation material, commonly used for insulation and sealing of walls, roofs, floors and other parts of buildings, industries and commercial places. Polyurethane foam is a material that is mixed with two components (component A and component B) and sprayed through a spraying device. It has excellent thermal insulation and sealing effects.

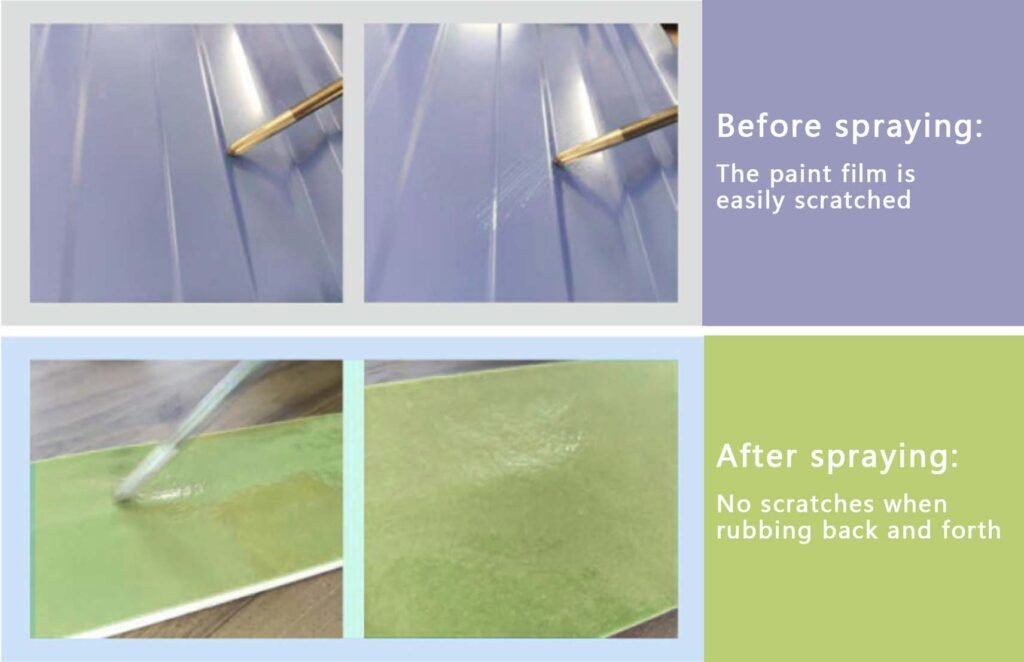

Features of Spray Foam Insulation

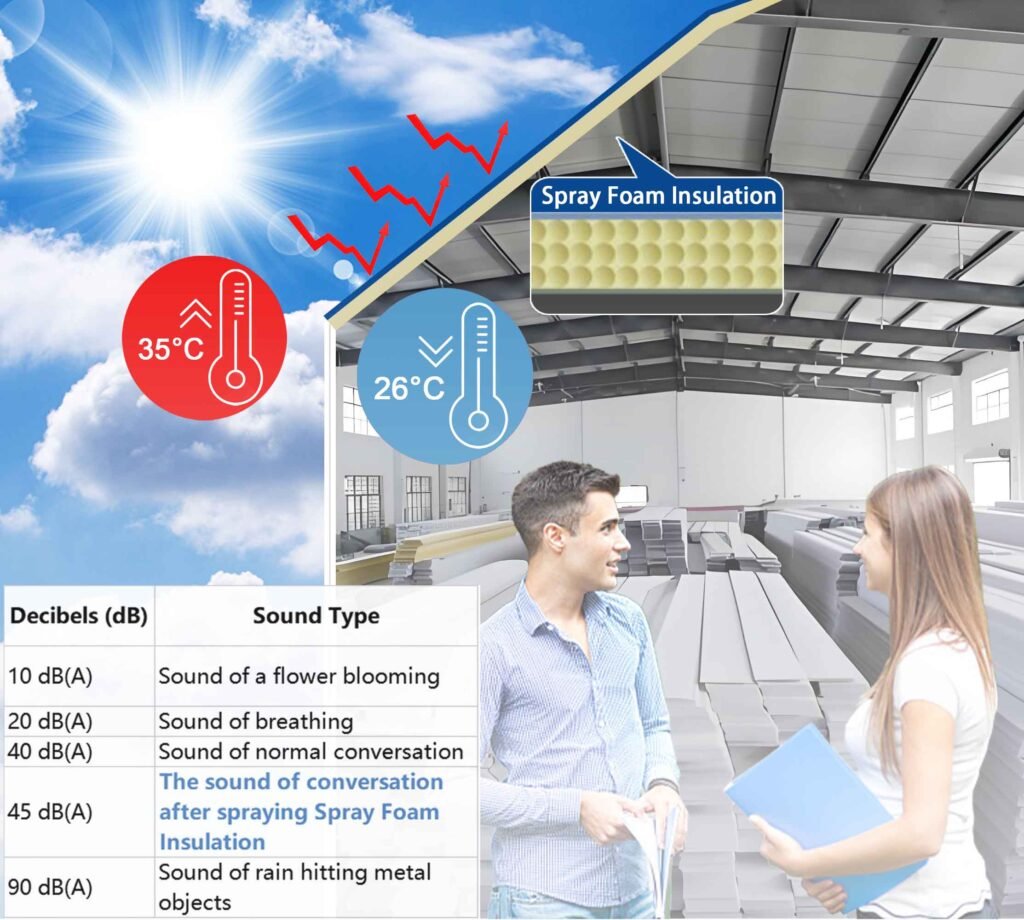

1,Heat insulation and noise reduction

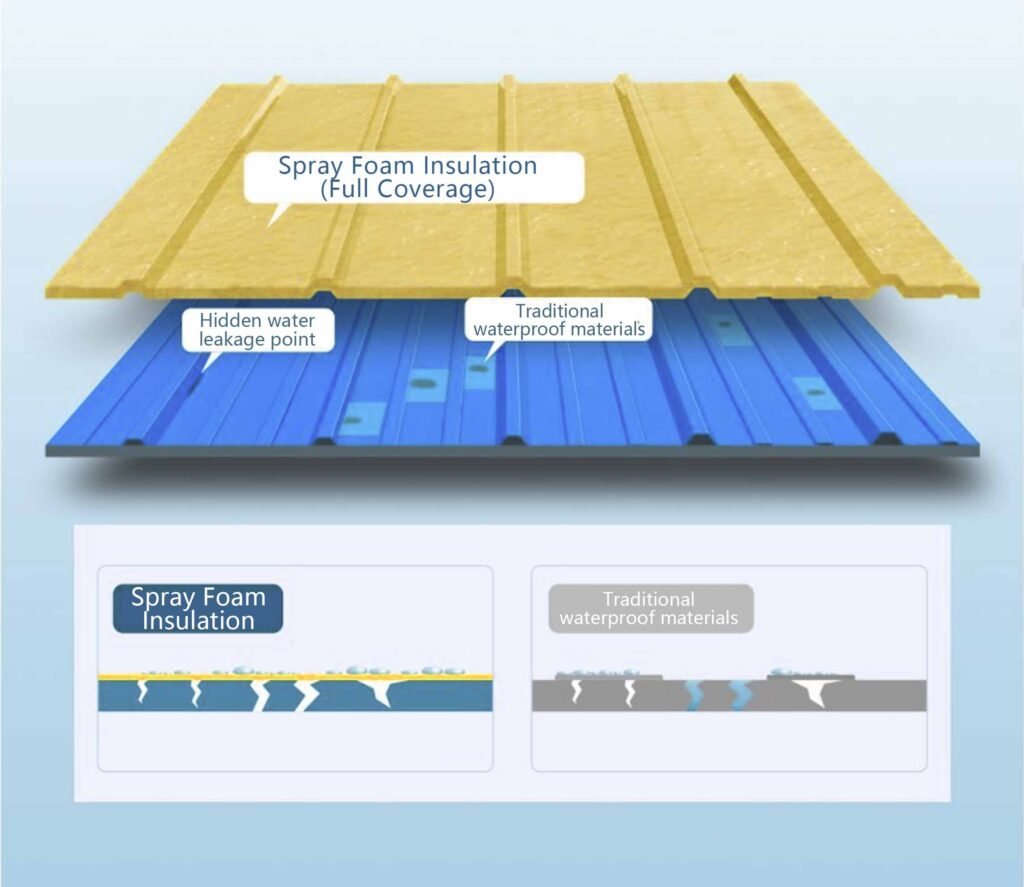

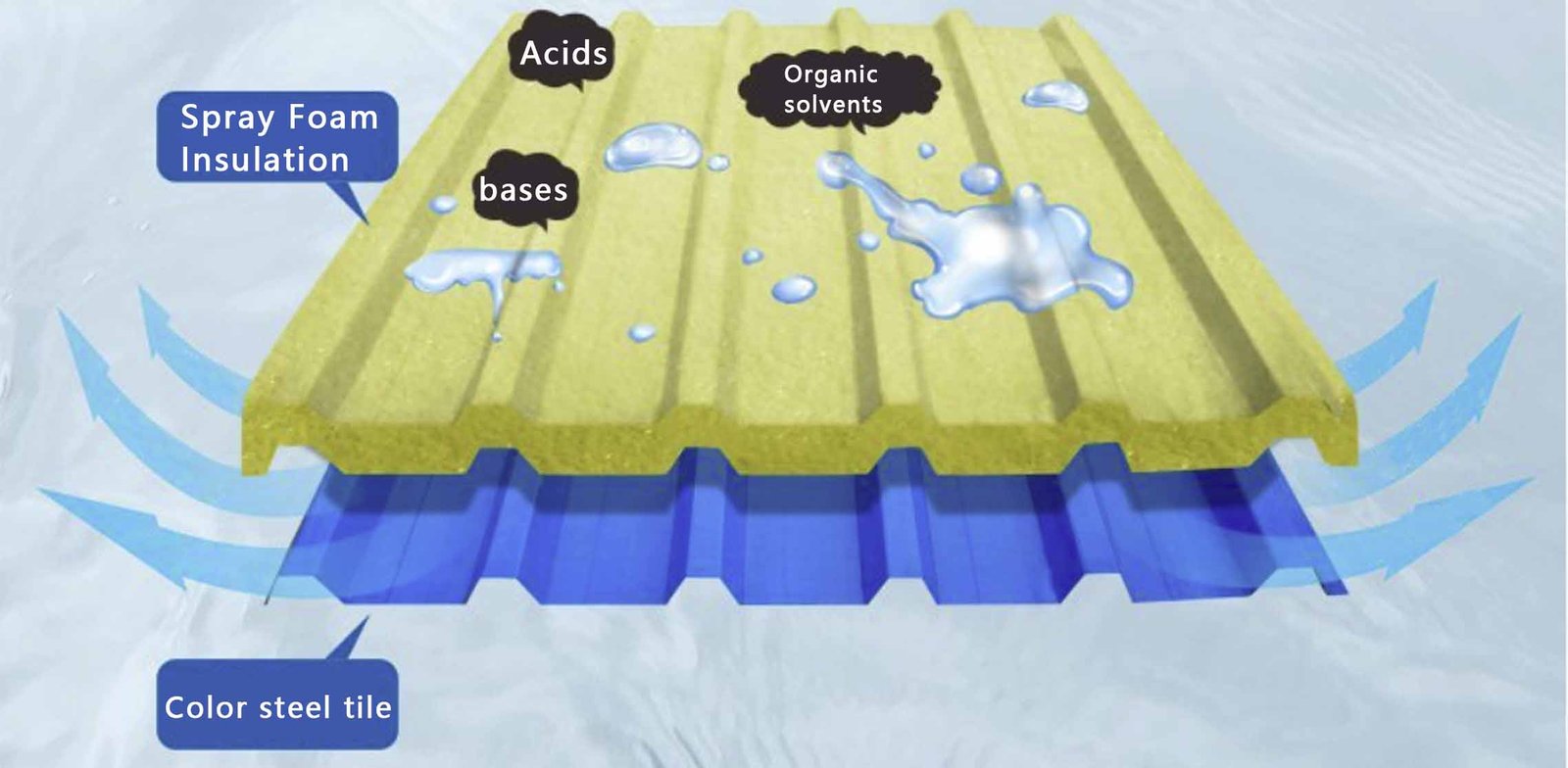

2,Water Proof

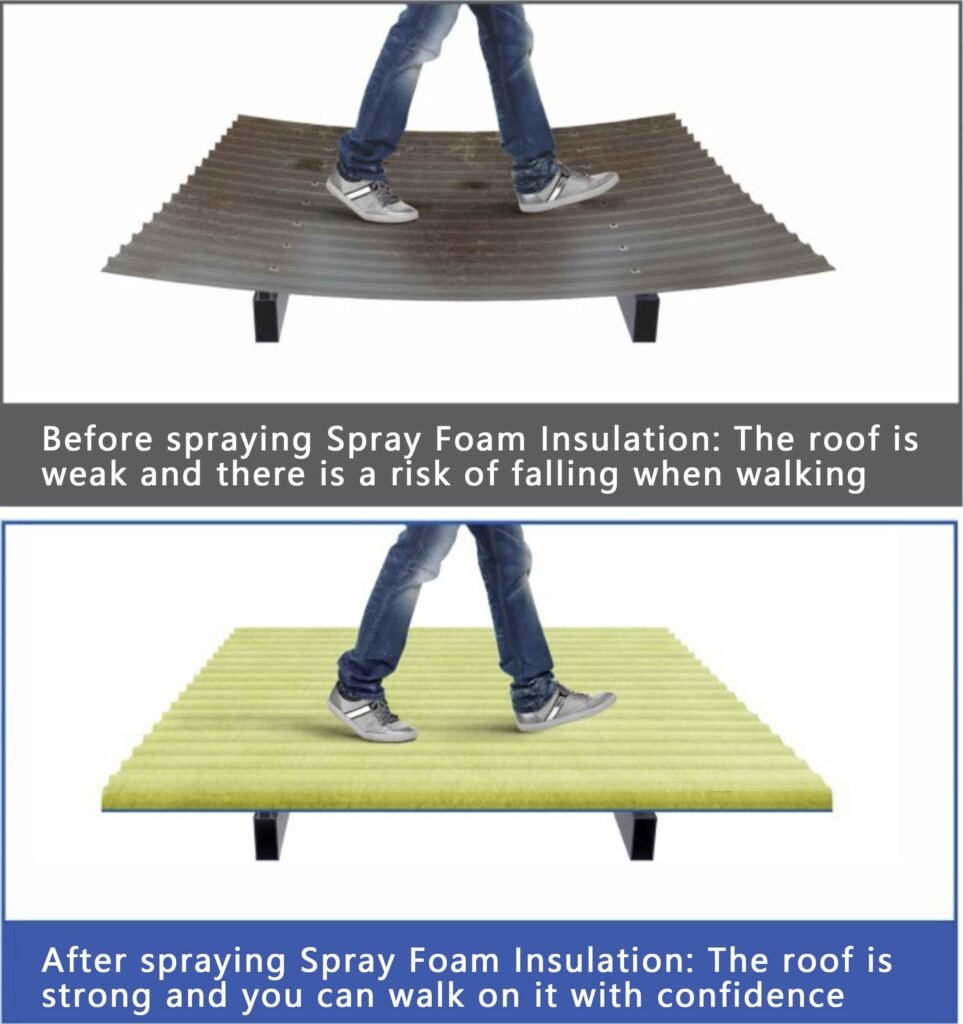

3,Enhanced pressure resistance

4,Durable

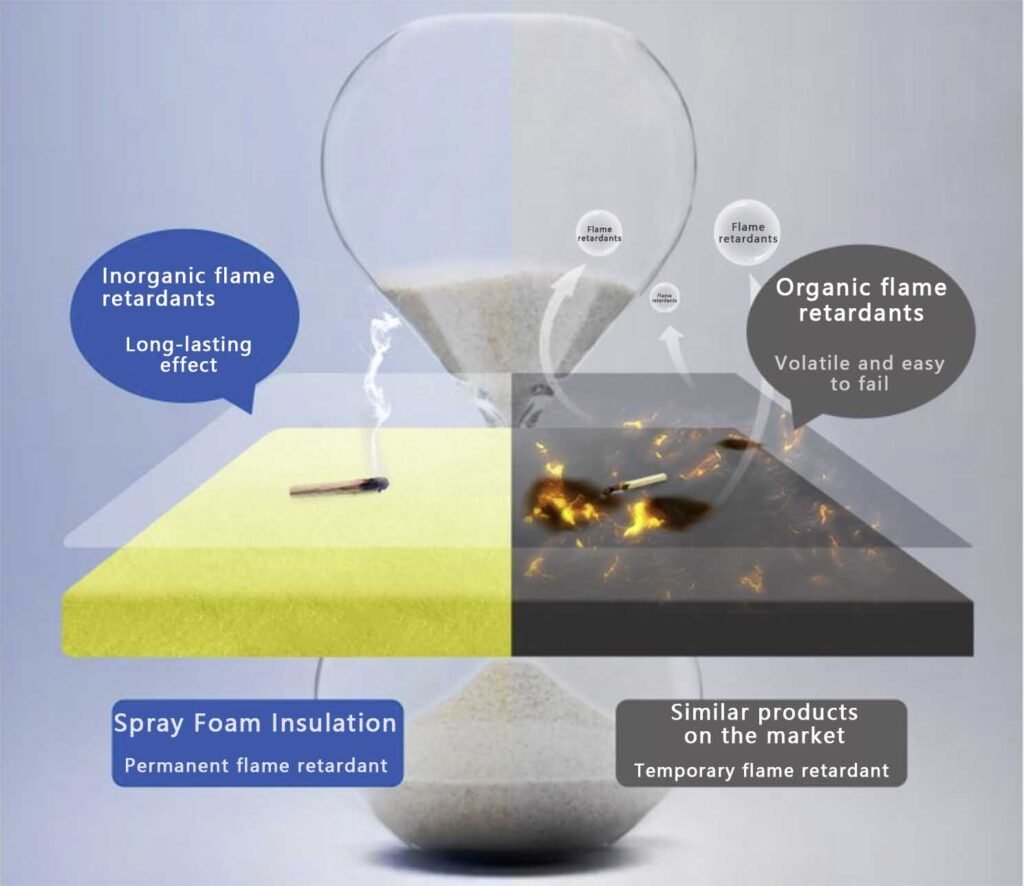

5,Fireproof

6,Anti-corrosion

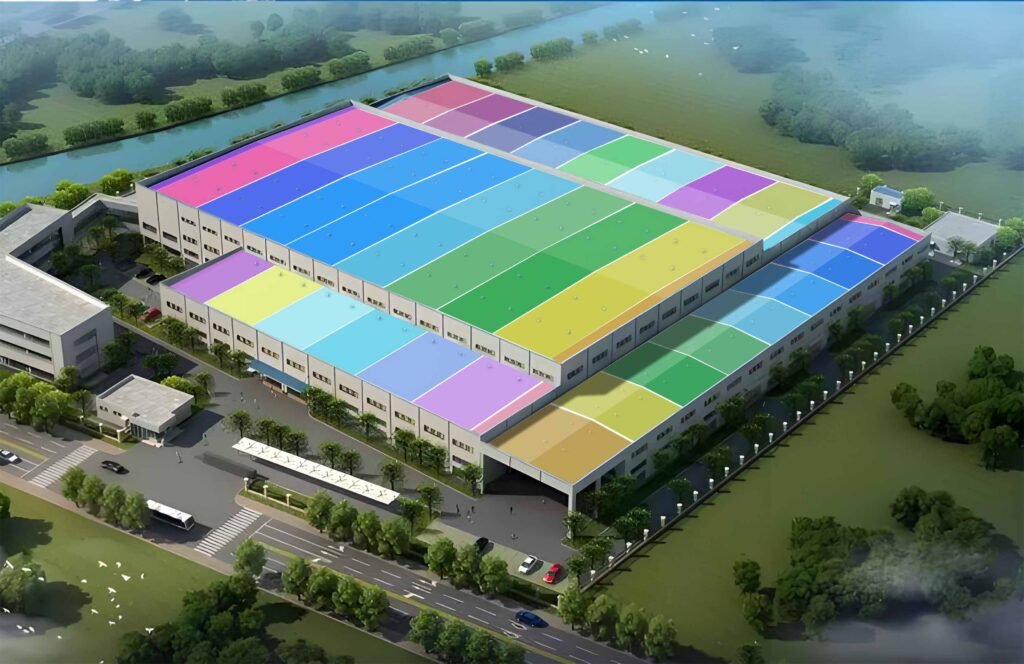

7,Beautiful

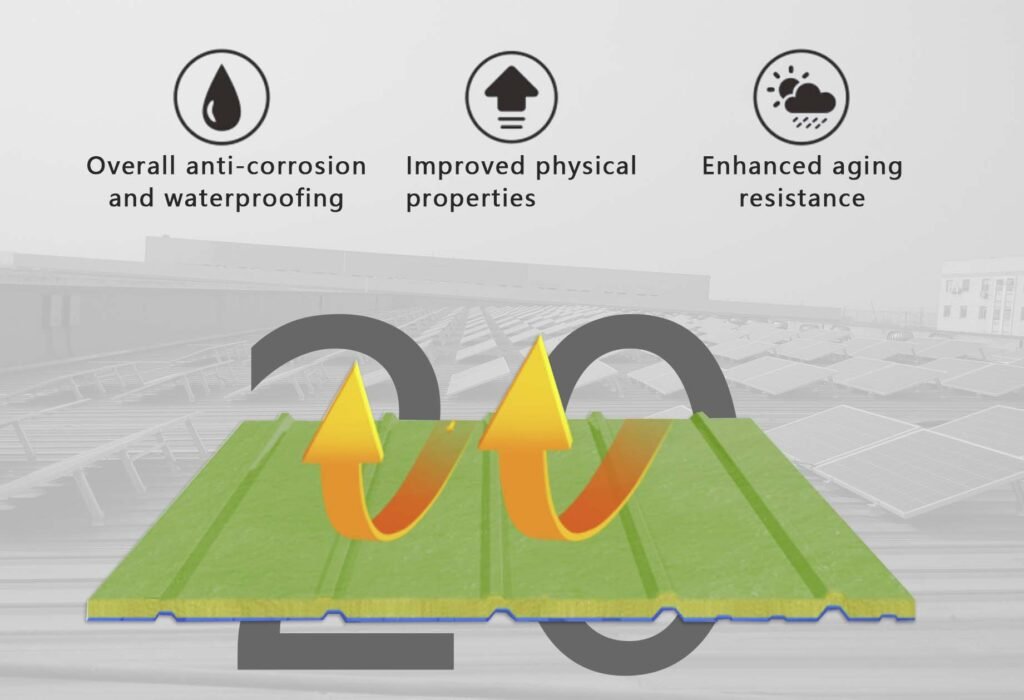

Photovoltaic Applications

1,Overall anti-corrosion and waterproof

2,Physical performance improvement

3,Extend service life

Spray Foam Insulation Construction Steps

1,Cleaning the surface

2,Roller anti-rust primer

3,Spray Foam Insulation Construction

4,Polyurea Topcoat Construction

Spray Foam Insulation Construction Steps

Factory roof

Photovoltaic roof

Steel structure roof

Terrace

Bathroom