Your Trusted Supplier Of Polyurea Coatings

MPU polyurea coatngs is an innovative aliphatic, slow-reacting, high-performance coating in the polyurea industry, known as the third generation of polyurea.

MPU specializes in polyaspartic resins, amine compounds, and latent curing technology. After years of product development, we have launched a cost-effective series of polyaspartic resins and amine compounds to meet various application needs. Our products are used in wind and hydropower anti-corrosion, flooring, exterior walls, civil waterproofing, furniture, and automotive industries.

We offer OEM/ODM services, customizing packaging to match your brand colors. With our chemical expertise, we are confident in delivering solutions that exceed your expectations.

Definition of Polyurea

Polyurea Coatings

Polyurea is a type of synthetic polymer produced by the reaction of a diamine and a diisocyanate, characterized by its urea linkages, high durability, and excellent waterproofing and protective properties.

Compared to epoxy and polyurethane coatings, polyurea offers superior corrosion resistance due to its exceptional chemical resistance and flexibility, making it the preferred choice for protecting surfaces in harsh, corrosive environments.

Features of Polyurea

1, SUPERIOR DURABILITY

MPU COATINGS’ third generation polyurea coatings provide long-lasting protection for up to 25 years. This durability ensures a resilient and high-performance surface for a wide range of applications.

2, WATERPROOF AND UV PROTECTION

Our coatings provide strong protection against water and UV rays. Ideal for both indoor and outdoor environments, they maintain their integrity and appearance in harsh conditions.

3, EASY APPLICATION

Coatings can be applied seamlessly using spray or brush. Flexible and convenient application.

4, VERSATILE APPLICATION

Suitable for a variety of environments including swimming pools, industrial & commercial flooring, residential flooring and industrial corrosion protection.

5, SUPERIOR Abrasion and Chemical Resistance

Polyurea coatings are resistant to abrasion, impact and chemical spills, making them suitable for high traffic areas and industrial applications. Their rugged properties ensure they can withstand demanding environments.

Our polyurea coatings have a non-slip surface and are flexible, slip and fall resistant, increasing the safety of your employees and family.

7, Beautiful and Low Maintenance

Available in a variety of colors and quartz sands, our coatings provide a beautiful and cohesive look. They are also easy to clean and maintain, reducing maintenance efforts in residential and commercial spaces.

What are the application scenarios of polyurea?

Polyurea coatings provide seamless waterproofing and exceptional crack resistance, making them ideal for swimming pools. Unlike epoxy or fiberglass, polyurea adapts to structural movement without cracking and offers superior chemical and UV resistance, ensuring long-lasting performance. For residential and commercial pools, polyurea delivers a durable, low-maintenance, and cost-effective solution.

Polyurea coatings are the ideal choice for residential applications, offering unmatched durability, waterproofing, and flexibility. Whether used for garage floors, patios, or pool surfaces, polyurea ensures a seamless finish that resists cracks, stains, and daily wear. Compared to traditional materials like epoxy, polyurea provides superior UV resistance and longevity, maintaining its appearance and performance for years. For homeowners seeking a low-maintenance, cost-effective, and reliable solution, polyurea delivers lasting value.

Polyurea coatings offer unparalleled performance for industrial flooring, combining exceptional durability, chemical resistance, and rapid curing to minimize downtime. With seamless coverage, these coatings provide a smooth, waterproof surface that withstands heavy machinery, foot traffic, and exposure to harsh chemicals. Their impact resistance and slip-resistant properties ensure long-lasting protection and a safer working environment. Easy to clean and maintain, polyurea-coated floors reduce maintenance costs while offering temperature stability and environmental benefits.

Polyurea coatings are the ideal choice for commercial flooring, providing exceptional durability, chemical resistance, and impact protection. Designed to withstand high foot traffic, spills, and daily wear, these coatings offer a seamless, waterproof surface that enhances floor longevity. With slip-resistant options, they improve safety in spaces like retail stores, offices, and hospitals. Easy to maintain and highly resistant to stains and abrasions, polyurea coatings deliver a cost-effective, low-maintenance flooring solution built to perform under the toughest conditions.

Polyurea garage floor coatings provide exceptional durability and chemical resistance, making them perfect for high-traffic, high-impact areas. These coatings create a seamless, waterproof surface that resists oil, grease, and stains, keeping your garage floor looking pristine. With slip-resistant properties, polyurea coatings enhance safety, even in wet conditions. The long-lasting finish is easy to clean, reducing maintenance costs while offering a cost-effective, high-performance solution. Whether for residential or commercial garages, polyurea coatings provide the strength and protection needed for long-term use.

Polyurea coatings offer exceptional durability and protection for school floors, withstanding high foot traffic, spills, and daily wear. These coatings create a seamless, waterproof surface that resists stains, chemicals, and abrasions, ensuring long-lasting performance in classrooms, hallways, and gymnasiums. With slip-resistant options, polyurea coatings improve safety for students and staff. Easy to clean and maintain, they reduce downtime and maintenance costs, providing a cost-effective, low-maintenance solution for educational facilities. Polyurea is the ideal choice for schools seeking high-performance flooring that can endure the demands of busy environments.

Polyurea coatings are ideal for hospital environments where hygiene, durability, and safety are critical. The seamless, non-porous surface prevents bacteria growth and is easy to clean, ensuring strict sanitation standards. Compared to traditional coatings, polyurea offers superior chemical resistance to withstand frequent cleaning with disinfectants, while its anti-slip properties enhance safety in high-traffic areas. Perfect for hospital floors, walls, and sterile areas, polyurea provides a long-lasting, low-maintenance, and hygienic solution tailored to healthcare facilities.

Polyurea coatings are ideal for shipping, storage, and refrigerated containers, offering seamless waterproofing and superior corrosion resistance through efficient spray application. Compared to traditional paints, polyurea is VOC-free, making it an eco-friendly choice with no harmful emissions. Its flexibility prevents cracking, while the durable, abrasion-resistant finish ensures long-term protection in harsh conditions. For new or refurbished containers, polyurea provides a sustainable, low-maintenance, and cost-effective solution.

Polyurea coatings provide seamless, durable protection for pipelines through efficient spray application. They offer exceptional corrosion resistance, waterproofing, and protection against chemicals and abrasion, making them ideal for oil, gas, water, and industrial pipelines. Unlike traditional coatings, polyurea’s flexibility prevents cracking from temperature fluctuations or structural movement, while its VOC-free formula ensures an eco-friendly solution. For both internal and external pipeline surfaces, polyurea delivers long-lasting, low-maintenance, and cost-effective protection.

History of Polyurea

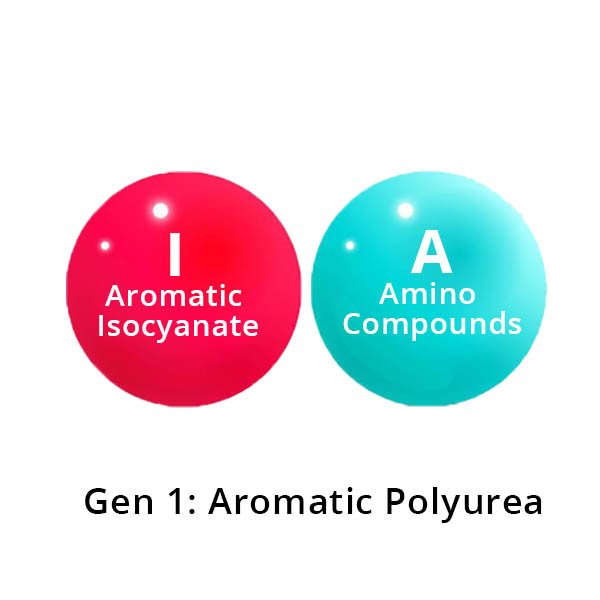

Gen 1: Aromatic Polyurea

The 1st generation of polyurea coatings emerged in the early 1990s. These coatings were characterized by their extremely fast reaction times, which posed challenges in terms of application and adhesion. Early polyurea formulations often suffered from poor adhesion and limited raw material availability, leading to a higher incidence of coating failures

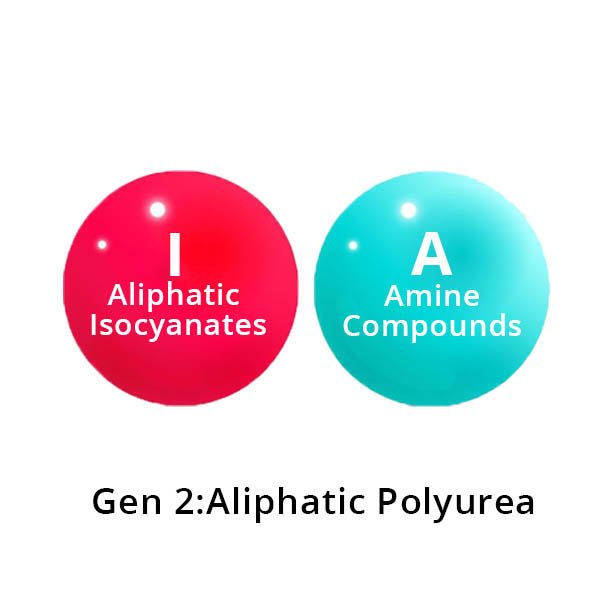

Gen 2 - Aliphatic Polyurea

By the early 2000s, the 2nd generation of polyurea coatings had been developed. These coatings featured significant improvements in hardness, chemical resistance, and reduced volatile organic compounds (VOCs). The advancements in raw materials, such as the introduction of secondary diamines, allowed for better control over the gel times, enhancing the adhesion and overall performance of the coatings

Gen 3 - Polyaspartic Polyurea

Polyaspartic polyurea is the 3rd generation of polyurea, it’s an aliphatic polyurea coating derived from the reaction of an aliphatic polyisocyanate with an aliphatic diamine (specifically a polyaspartic ester). It is essentially a slowed-down version of polyurea, allowing for easier application while retaining many beneficial properties.

Why Choose MPU Polyurea Coatings

MPU Polyurea Coatings

MPU polyurea coatings are a series of products with diverse performance consisting of polyaspartic acid ester resins or other amino compounds, and bio-based polyol resins, used in conjunction with UV-resistant aliphatic modified curing agents.

This is the third-generation handcrafted polyurea coating, which can be sprayed or hand-brushed. All main materials are produced by MPU. Suitable for various types of ground substrates.

MPU polyurea coating technology offers the most durable coating, with fast drying times and unmatched quick recovery, making it ideal for one-day installations.

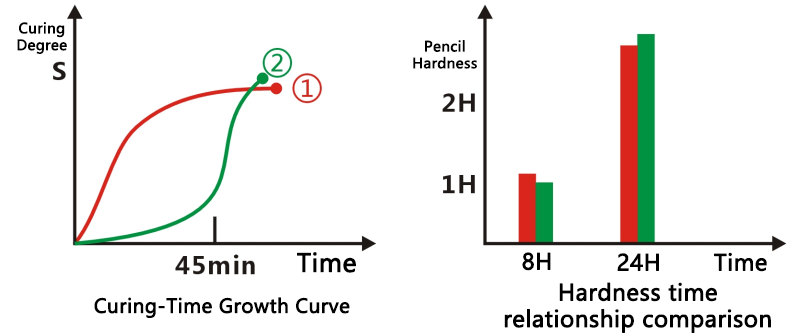

Latent Curing Technology

High-performance polyurea and polyurethane often suffer from rapid reaction speeds and short working times, causing significant challenges in practical applications. MPU polyurea polyurethane utilizes latent curing technology to effectively reduce the initial reactivity of the material, extending the working time without compromising the final curing speed and material performance

Advantages Of MPU Polyurea Coating

- Extended open time, long working time

- Rapid hardness development, reducing construction period

- High crosslink density

- High final hardness

- High chemical resistance, excellent anti-corrosion properties, suitable for heavy-duty anti-corrosion applications

- Toughness, hard but not brittle, impact resistant

- Superior wear resistance

- Dense coating film, special polyol and amine technology, easy to clean and anti-stain

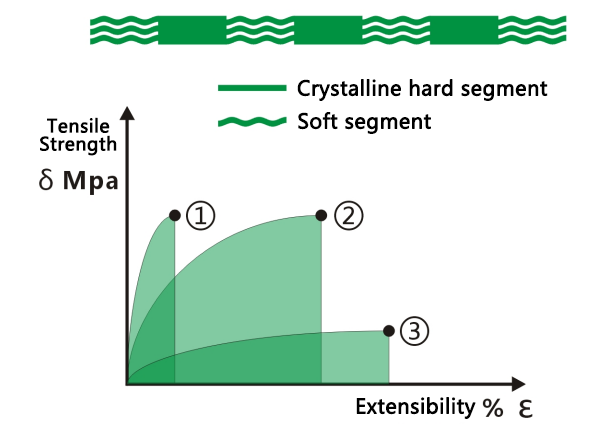

Impact Absorption, Abrasion Resistance, and Hardness

MPU utilizes unique polyol technology, ensuring material performance. The polyol components provide suitable toughening, guaranteeing MPU’s impact resistance. MPU contains a substantial amount of urea and amine bonds, which can absorb and release various external stresses. As demonstrated in the tensile performance graph, MPU is a high energy-storage material. It offers hardness while resisting impact and abrasion damage. This is especially important for heavy-duty flooring systems and extending the material’s lifespan.

| Inspection Item | Index Value | Inspection Result | Single Item Determination |

|---|---|---|---|

| Abrasion Resistance (750g/500r), g | ≤0.030 | 0.006 | Pass |

| Impact Resistance (1000g steel ball load) | No cracks, no peeling off the coating | No cracks, no peeling off the coating | Pass |

| Hardness, Pencil Hardness (scratch) | Specified | 6H | Measured Value |

Note: The above data is obtained by the Chemical Industry Synthetic Materials Aging Quality Supervision and Inspection Center.

Typical Tensile Curves

- Tensile Curve of Rigid Materials: Epoxy Resin

- Tensile Curve of MPU Polyurea Resin

- Tensile Curve of Elastic Materials: Polyurethane

E=∫δdε

| MPU exhibits good alkali resistance | |||

|---|---|---|---|

| Item | Standard Value | Test Result | Judgment |

| Alkali Resistance (20% NaOH, 72h) | No blistering, no peeling, slight discoloration allowed | No blistering, no peeling, slight discoloration | Qualified |

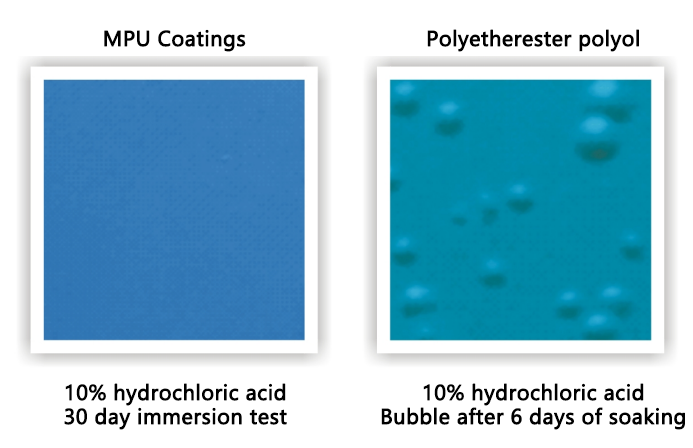

Water And Chemical Resistance

1. Unique Properties of Polyol Resin in MPU Polyurea Polyurethane

The polyol resin used in MPU polyurea polyurethane features a low ether oxygen atom content and an aromatic structure, leading to high hydrophobicity.

2. Hydrophobicity and Water Resistance

The high hydrophobicity of MPU polyols results in low moisture sensitivity and excellent water resistance during the isocyanate curing process.

3. Superior Heat and Acid-Base Resistance

Compared to typical polyether-based polyurethanes, MPU polyurea polyurethane’s increased aromatic structures offer superior heat resistance and acid-base resistance.

4. Absence of Hydrolyzable Ester Bonds

Unlike polyester-based polyurethanes, MPU polyurea polyurethane does not contain easily hydrolyzable ester bonds, enhancing its durability.

5. Enhanced Solvent Resistance and Mechanical Strength

The combination of aromatic and aliphatic chains, along with numerous urea bonds, provides MPU with excellent solvent resistance, acid and alkali resistance, water resistance, mechanical strength, and hydrophobicity.

MPU exhibits good acid resistance

| Item | Standard Value | Test Result | Judgment |

|---|---|---|---|

| Acid Resistance (10% H₂SO₄, 48h) | No blistering, no peeling, slight discoloration allowed | No blistering, no peeling, no discoloration | Qualified |

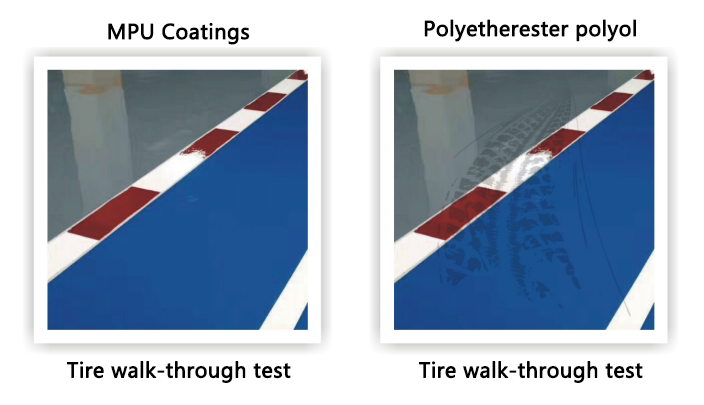

MPU shows good tire imprinting performance

Note: The above data is obtained by the Chemical Industry Synthetic Material Aging Quality Supervision and Inspection Center

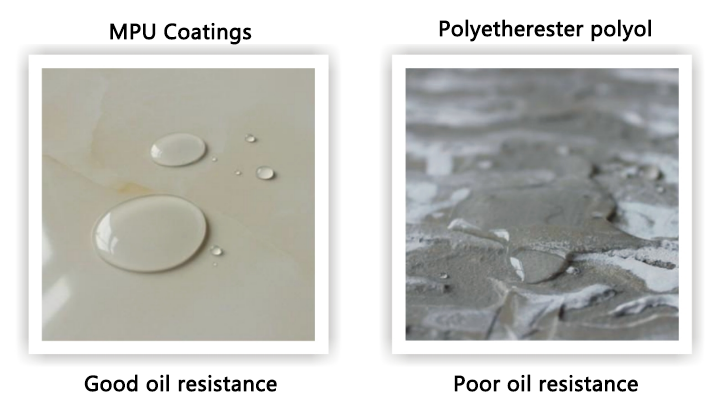

MPU® shows good oil resistance

| Item | Standard Value | Test Result | Judgment |

|---|---|---|---|

| Oil Resistance (120# Solvent Oil, 72h) | No blistering, no peeling, slight discoloration allowed | No blistering, no peeling, no discoloration | Qualified |

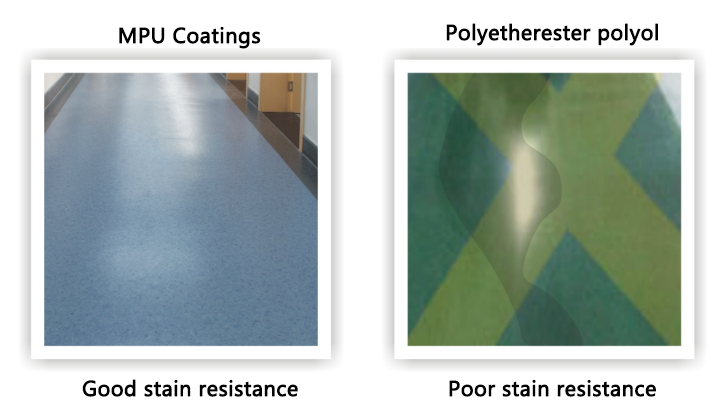

MPU® shows good stain resistance

| Item | Standard Value | Test Result | Judgment |

|---|---|---|---|

| Water Resistance (168h) | No blistering, no peeling, slight discoloration allowed, recovers after 2 hours | No blistering, no peeling, no discoloration | Qualified |

Packaging And Storage Period

Customizable packaging

We offer OEM/ODM services, with the flexibility to customize packaging sizes and designs to perfectly match your brand colors.

- Conventional packaging: 200 kg/drum, 25 kg/drum, 5 kg/drum.

- 200KG/Drum, 4Dmms’pallet, 16Ton/20GP

- The shelf life of in the original closed container is 12 months.

NOTICE: It should be kept away from fire source and stored in a cool, dry, and ventilated environment.

Hand-applied Polyurea Coatings

Polyurea construction method

MPU polyurea polyurethane adopts latent curing technology to appropriately reduce the initial reaction activity of the material, prolong the material operation time, and does not affect the final curing speed and material performance of the material.

MPU polyurea coating can be applied manually by brushing or scraping with a roller brush, a brush, or a trowel, or it can be efficiently sprayed with spray equipment. The construction methods are flexible and diverse.

Polyurea Coatings

Applications of Polyurea

Durable,Attractive protective & flooring polyurea coatings. That Stands Up to Anything. For Today’s Commercial & Industrial Facilities.

Quality Management System

Color Service

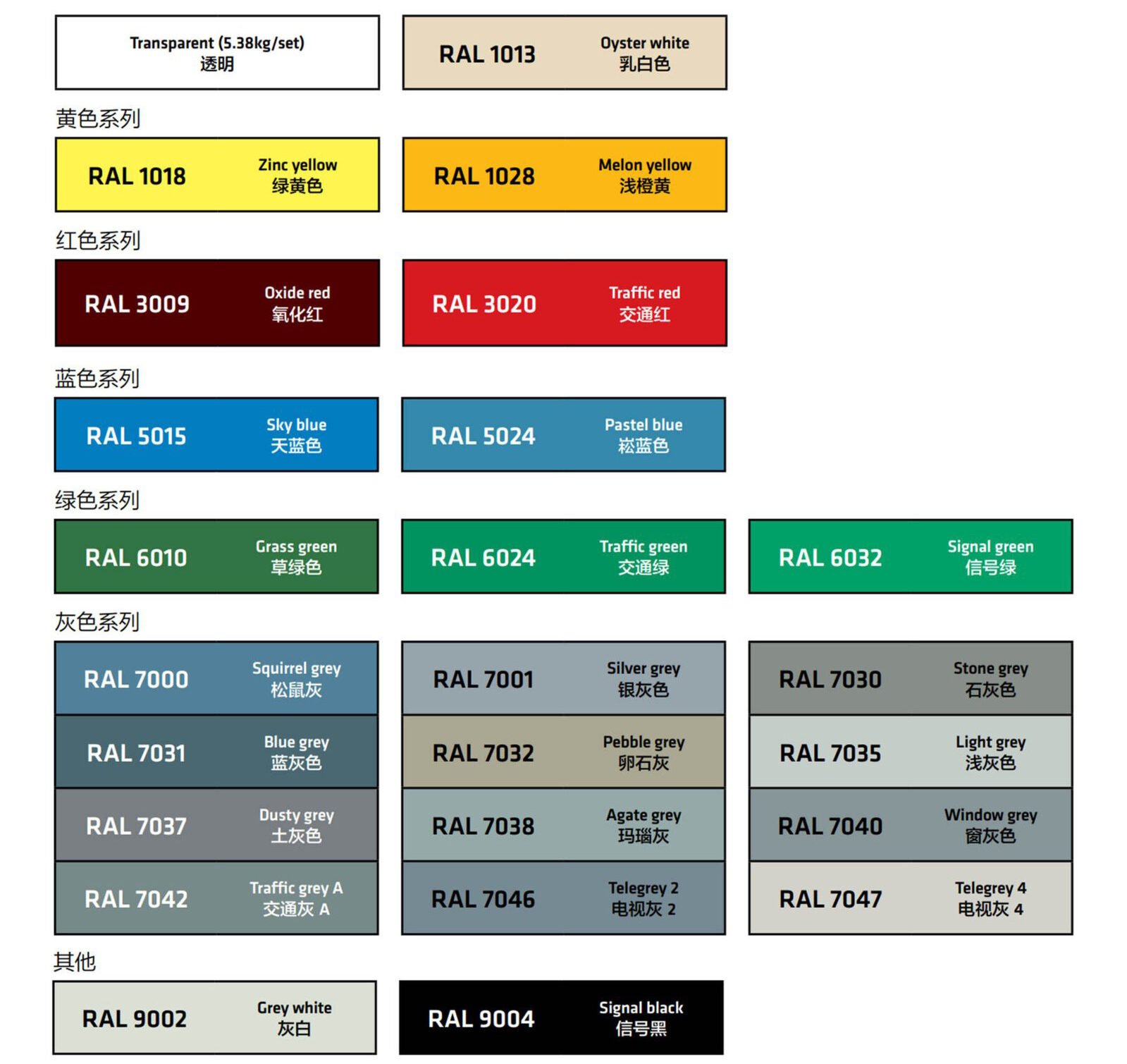

MPU Coating Floor Color Card

The MPU Coating floor color card is derived from the German RAL color card, a highly respected standard among color professionals in the international industrial, architectural, and design sectors. The RAL color standard is extensively used in various color matching designs and color calibration processes.

Please note that due to variables such as lighting conditions and display differences, the colors on the electronic card may appear different from the actual paint colors. Therefore, this color card is intended for reference purposes only and should not be used as a standard sample.

Colors can be customized

Colored Quartz can be used with all MPU COATINGS Systems

Decorative flakes can be used with all MPU COATINGS systems

MPU COATINGS Common Colors

Frequently Asked Questions (FAQ)

Polyurea is an elastomer derived from step-growth polymerization, which involves combining a synthetic resin and an isocyanate reactive material. It is renowned for its rapid curing time, durability, and resistance to various environmental factors.

Polyurea is used in a wide range of applications including waterproofing, coatings for pipelines, secondary containment, tank linings, flooring, and protective coatings for concrete and steel structures.

Polyurea offers superior benefits such as faster curing times, greater flexibility, excellent abrasion resistance, and strong chemical resistance compared to traditional materials like epoxy and polyurethane.

Polyurea coatings provide outstanding durability, resistance to chemicals and abrasions, waterproofing capabilities, quick application and curing times, and the ability to adhere to a variety of substrates.

Yes, polyurea can be applied in a wide range of temperatures, from sub-zero to high heat environments, making it versatile for various climatic conditions.

Polyurea has an exceptionally fast curing time, typically ranging from seconds to minutes, allowing for quick project turnaround and minimal downtime.

Polyurea is environmentally friendly as it contains no volatile organic compounds (VOCs), solvents, or other hazardous substances, making it safe for use in sensitive environments.

Polyurea can be applied to numerous surfaces including concrete, steel, wood, and other metals, as well as various types of plastics and foam.

The longevity of a polyurea coating depends on the specific application and environmental conditions but typically, polyurea coatings can last for many years, providing long-term protection and performance.

Polyurea coatings require minimal maintenance. Regular cleaning and periodic inspections for any signs of wear or damage will help ensure the longevity and performance of the coating.

Looking for a Material Safety Data Sheet? (MSDS / SDS) Click the link to complete a request form.